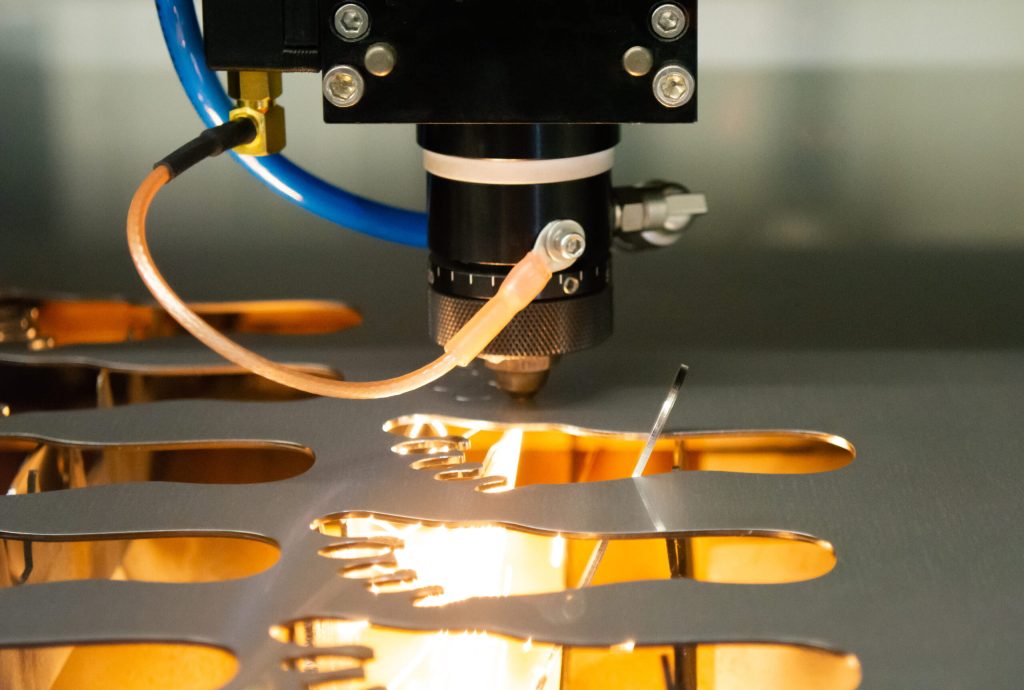

Laser Cutting Services

Xtmadeparts provides high quality laser cutting and engraving services for a wide variety of materials and products. We are able to provide 2D and 3D product designs in a variety of colors. We excel at laser cutting hard and delicate materials, difficult and complex projects, and both large and small projects.

Professional Laser Cutting

If you are looking for a more affordable production technology than other options, then you may want to consider laser cutting services. It is ideal for making complex parts with fine details that are not possible using a punch press, without the cost of tooling. It can also hold tighter tolerances than water jet cutting.

Laser cutters can produce prototype parts in as little as two weeks, with fine details and tighter tolerances, and fast production schedules. Laser cutting is also ideal for medium to high volume applications.

Laser Cutting Manufacturers

At Xtmadeparts, we offer a full range of metal laser cutting manufacturing solutions. Our laser cutting services are designed to be flexible and efficient. At our facility in Shenzhen, China, we operate precision laser cutting equipment with lights-out capabilities. This allows us to provide high-volume, tight-tolerance work at competitive prices. Plus, our team of engineers, each with years of industry experience, allows us to provide quality laser cutting capabilities for a wide range of materials, in varying types, grades, and thicknesses, to customers around the world.

Whether you need to mass produce a product part or need a design cut out of a piece of steel for aesthetic reasons, we can help. Our knowledgeable team of professionals will work with you to help you develop, design, and manufacture the metal parts you need in a timely manner. Our engineers will work with you to ensure we develop an optimized process that saves you money and reduces waste.

Our Laser Cutting Capabilities

We are able to accommodate sheet sizes up to 83″ x 163″ of the following types of materials: carbon steel and other alloy steels up to 1.00″ thick, aluminum up to 0.500″ thick, stainless steel up to 0.625″ thick, and titanium up to 0.25″ thick. Our laser cutting equipment, combined with automated material handling systems, excels at cutting long-run electrical enclosures, cabinets, medical devices, and OEM components. All products can be custom marked and receive material traceability reports. In addition, our comprehensive logistics services: JIT shipping, Kanban inventory, scheduled releases, MRP forecasting, and EDI capabilities. We are able to handle small batches, large batches, and consolidated orders. Delivery time is typically two weeks, with expedited service available.

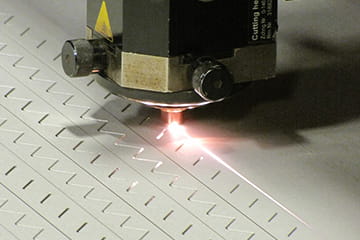

Fiber Optic Laser

- Blinding max cutting speed of >1,800 inches per minute

- 0.008 Kerf

- Thickness capacity

- Aluminum: 0.020″ – 0.500″

- Stainless Steel 0.024″ – 0.500″

- CRS 0.024″ – 0.750″

- Copper 0.020″ – 0.125″

Fiber Optic and CO2 Lasers

- Feature size tolerance +/- 0.002″

- Linear and position tolerance +/- 0.005″

- 5′ x 10′ sheet processing size

Laser Cutting Machine Types

Our laser cutting shop has a variety of advanced equipment that can process a variety of materials with high precision and efficiency, and quickly provide customized parts for customers in a variety of industries.

Fiber Laser Cutting

CO2 Laser Cutting

Nd:Yag Laser Cutting

Have a special request or a creative laser cutting idea?

We will work with you to develop and refine concepts, create new ideas and plans, design artwork, or leverage what you have already created. We are known for bringing visions to life and adding that special touch to projects that need to stand out. To get started with a free laser cutting quote or get answers about laser cutting materials, contact us today!

Laser Cutting Materials

We have the capability to work with a variety of materials, including:

- Mild Steel

- Stainless Steel

- Aluminum

- Tool Steel

- Armor Plate

- Inconel

- Titanium

- Hastelloy

- Brass

- Acrylic

- Wood

- Exotic Metals

- Other Materials

Laser Cut Part Finishing Services

- Anodizing

- Bending

- Countersinking

- Hardware

- Plating

- Powder Coating

- Tapping

- Tumbling

What is laser cutting?

Laser cutting is a subtractive manufacturing process where a machine uses a laser beam to cut parts from a sheet. However, the laser beam does not cut or melt, but rather vaporizes the material using its intense laser energy, thus preventing the material from catching fire or degrading. Laser cutting machines are controlled by a computerized digital system, which allows them to produce any 2D part (changing the command will change the shape) and also allows them to provide high precision for thousands of parts.

Advantages of Laser Cutting

- Precision: Laser cutting offers a level of precision that is difficult to achieve with other methods. If your project requires a fine design, laser cutting is a good choice. The very narrow cutting width allows for sharp edges and corners as well as small details. Also, since there is no vibration, the machine can cut smaller parts than a router.

- Smooth Edges: Laser cutting leaves perfectly smooth, clean edges, which means there is no need for sanding or other post-cutting work.

- Fast: Our powerful, modern equipment enables us to complete your project quickly and meet your deadlines.

- Cost-Effective: Laser cutting is extremely cost-effective compared to other methods.

- Flexible: Lasers can cut a wide range of materials and thicknesses, so your options are not limited.

What parts can be made using laser cutting?

Laser cutting is ideal for creating panels, such as those found on industrial equipment, control panels, user interfaces, musical instruments, and medical devices. This is especially true for the electronics industry, as nearly all electronic devices are housed in some kind of housing.

Laser cutting is also ideal for creating small mechanical parts from metals and plastics. For example, tiny gears used in complex mechanical devices can take advantage of the low-cost, high-precision capabilities of laser cutting.

Metal laser cutting can be used to create brackets and accessories, and our laser cutting services combined with our metal bending and finishing services can create market-ready 3D parts.

Industries We Serve

Whatever industry you’re in, we can cut the material to meet your expectations. And, even if laser cutting isn’t right for you, we offer many alternatives that may be more interesting to you. All you have to do is contact us. Our goal is complete customer satisfaction through the highest level of service. Whatever your project, we have a way to make your vision a reality.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Ready to get started on your next project?

From one part to thousands of parts, we can help you accelerate your sheet metal projects using laser cutting in a cost-effective way. The Xtmadeparts team can provide a range of solutions for your manufacturing needs. Talk to us today about your laser cutting project and how your project can take advantage of its high quality and accuracy.

News & Article

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…