CNC Turning Service

Our experienced machinists will provide you with cost-effective CNC turning solutions for your precision turned parts. High quality, tight tolerances, competitive pricing and fast delivery times.

About our company

Xtmadeparts uses innovative technology, scientific system management and a partner network to help customers simplify the procurement process and ensure that customers receive top-quality CNC turning parts that meet the highest quality and precision standards. Our commitment to excellence and dedication to transparency and efficiency have made us a key player in promoting the production and delivery of CNC turning parts, further improving the quality and precision of parts in various industries.

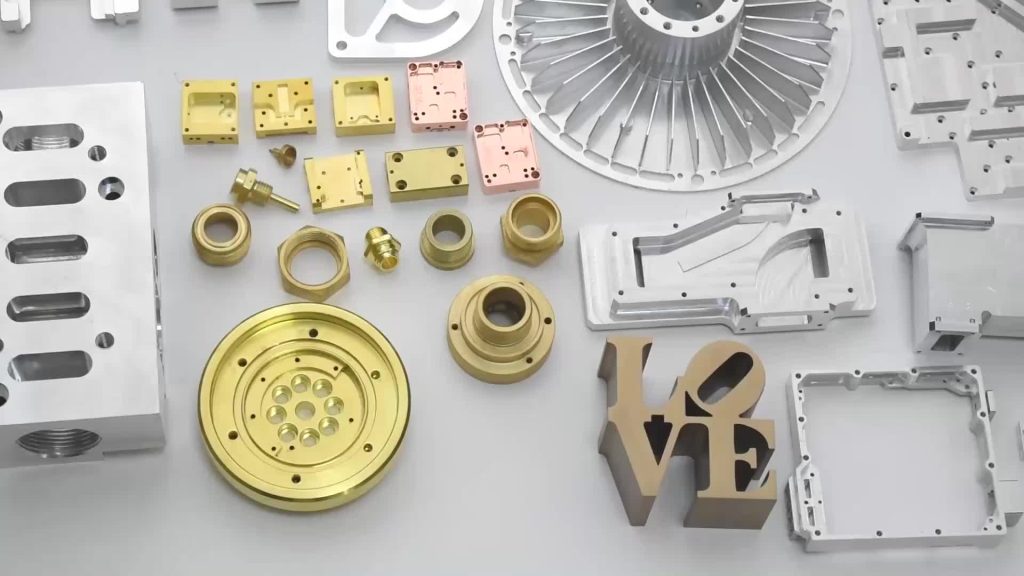

Precision Turned Parts Manufacturing

Xtmadeparts produces a wide range of turned parts and assemblies using advanced CNC lathes. We produce high-precision turned parts to the exact requirements of our customers’ designs. From the simplest parts to the most complex, we can provide almost any turned part you can think of. Whether machining a few, tens of thousands to hundreds of thousands or even more parts.

Based on your design files or working with you as needed, we will develop the design of the turned part to meet the fit, form and function required for your project. Our in-house design team provides valuable engineering assistance and support to help you turn parts as efficiently and economically as possible.

With an experienced team of engineers, advanced equipment and state-of-the-art design software, our in-house lathe department can produce turned parts to any design. We can provide turned parts from 1/16 inch to 10 inches or larger in diameter. CNC technology allows us to accurately turn extremely complex geometries and hold tolerances to ±0.0005 inches or better. And we have uninterrupted manufacturing capabilities, including “lights out” production using automated CNC technology, which can achieve 24/6 all-weather production.

Design for Manufacturing (DFM)

We offer DFM services to help accelerate part production, streamline production processes, and reduce costs. Our engineering team will work with you as needed to optimize your design for manufacturability without changing the fit, form, or function of the turned part.

In-House Tool Shop

We design, manufacture, and maintain all of our own tooling for CNC turning projects. We monitor every step of the process to ensure precision and quality in the finished part. All tooling is custom made for each project, and we will maintain and service your tooling for the life of your project, whether you need 10,000 or 10 million parts per year. We offer additional in-house services to save your project time and money, shorten your supply chain, and reduce the potential for problems or oversights.

CNC Turning Part Materials

CNC turning can be performed with a wide variety of materials, including different metals and plastics. Below is a list of materials we commonly use. More material types and grades are available upon request.

Metals

- Aluminum

- Copper

- Brass

- Bronze

- Steel

- Stainless Stee!

- Magnesium

- Titanium

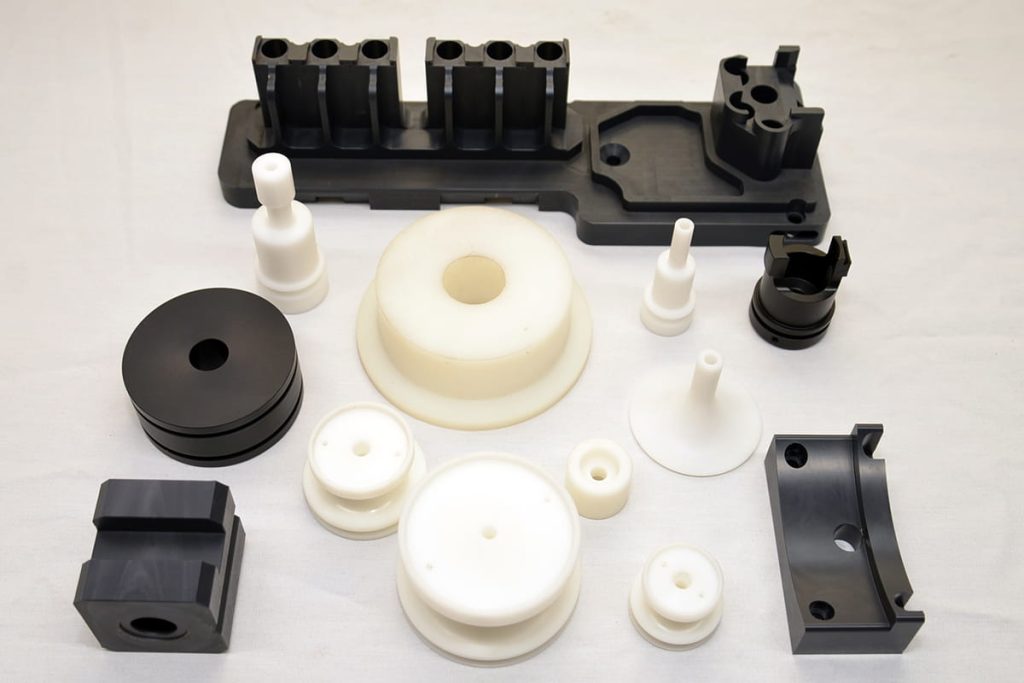

Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- HDPE

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- PTFE (Teflon)

- UPE

- Bakelite

- FR-4

Surface Finish Options

We offer a wide range of surface treatment options to improve the surface quality of your CNC turned parts. Surface treatments applied after machining can change the appearance, surface roughness, hardness, and chemical resistance of the produced parts.

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Finishes for Plastic

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

Ready to start your next project?

Are you ready to start your next project? Tell the details or send CAD files for a competitive quote today.

How does CNC turning work?

CNC turning is a manufacturing process in which a fixed cutting tool removes material from a rotating workpiece, shaping it into a cylindrical and symmetrical object. The process is performed using a computer-controlled machine, known as a CNC lathe. The CNC lathe is then programmed to move the cutting tool along the workpiece according to the shape and dimensions programmed into its software.

The CNC turning process typically begins with the raw material being secured to the lathe spindle, which spins the material at high speeds. The cutting tool removes small amounts of material until the desired shape and size are achieved. The removed material is called chips, which are removed by the machine. After the turning process is complete, the finished product is inspected and any necessary finishing or polishing is completed.

Key Differences Between CNC Turning and Milling

There are a number of differences between CNC turning and CNC milling, depending on the equipment. CNC turning is a process where the workpiece is rotated and a fixed tool is used to remove material. CNC milling is a different process where the tool is rotated and then moved along the fixed workpiece to remove material. Therefore, CNC turning is mainly used for projects that require cylindrical parts, while CNC milling is suitable for projects that do not require cylindrical features. In addition, CNC milling can be used as a secondary finishing operation to increase definition. Complex parts that require prismatic and cylindrical features can use a combination of milling and turning.

Our Quality Assurance Process

The company has a strict quality control system to ensure that all products meet customer requirements. Prior to delivery, we conduct comprehensive testing on our customers’ products to ensure that they meet specifications, including dimensional accuracy, surface finish, hardness and precision. We also utilize computerized measuring equipment to verify critical dimensions to ensure that every product we produce is of the highest quality.

In addition, we implement a strict quality assurance process including regular in-process inspections based on part requirements and first article inspection reports (upon request) to ensure that every precision machined component we produce is of the highest quality and manufactured to your specifications. Our commitment to quality ensures that every customer receives their products on time, with the highest accuracy and in accordance with their requirements.

Applications Of CNC Turning

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Request Your Free CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…