CNC Milling Services

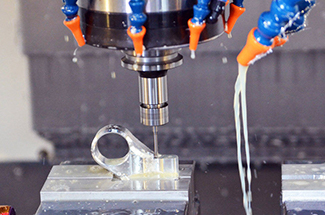

On-demand CNC milling services for rapid production of custom milled prototype and production parts in a variety of metal and plastic materials. Get milled prototypes and low-volume CNC milled parts at a low cost.

Searching for a dependable supplier of CNC-milled parts?

Our CNC milling processes can produce custom prototypes and end-use production parts. We use 3-axis milling and 5-axis indexed milling processes to manufacture a wide range of engineering-grade plastic and metal parts. With machined production parts, you can get more competitive pricing at higher quantities, in addition to First Article Inspection (FAI) reports, material certifications, and additional finishing options such as anodizing and chrome plating.

CNC Milling Process Types

From 3-axis basics to complex 5-axis projects, our precision CNC milling can quickly turn your designs into real parts.

3-Axis CNC Milling

4-Axis CNC Milling

5-Axis CNC Milling

CNC Milling Capabilities

We have state-of-the-art CNC milling equipment that can provide a full range of services including face milling, parting off, slotting, drilling, threading and more. We can typically machine parts up to 3″ x 457.2″. In addition, our high-speed vertical and horizontal machining centers can produce high-precision machined parts for many industries. We can provide CNC machined parts up to 24″ x 24″ x 28″ for horizontal milling and 64″ x 34″ x 30″ for vertical milling. We can handle 3, 4 and 5-axis machining with tolerances as close as ± .0002″.

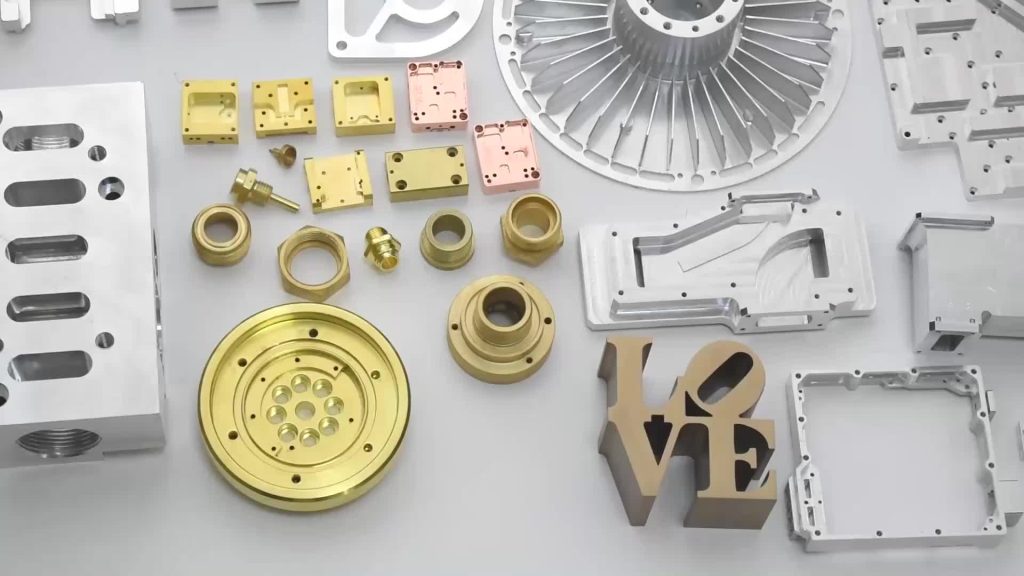

CNC Milling Materials

We stock a wide variety of production-grade plastic and metal materials suitable for a variety of part applications and industries. Materials verification ensures precision and durability. The broad material selection allows our customers to make the best choice for their unique project, improving the quality and performance of their products.

Metals

- Aluminum

- Copper

- Brass

- Bronze

- Steel

- Stainless Stee!

- Magnesium

- Titanium

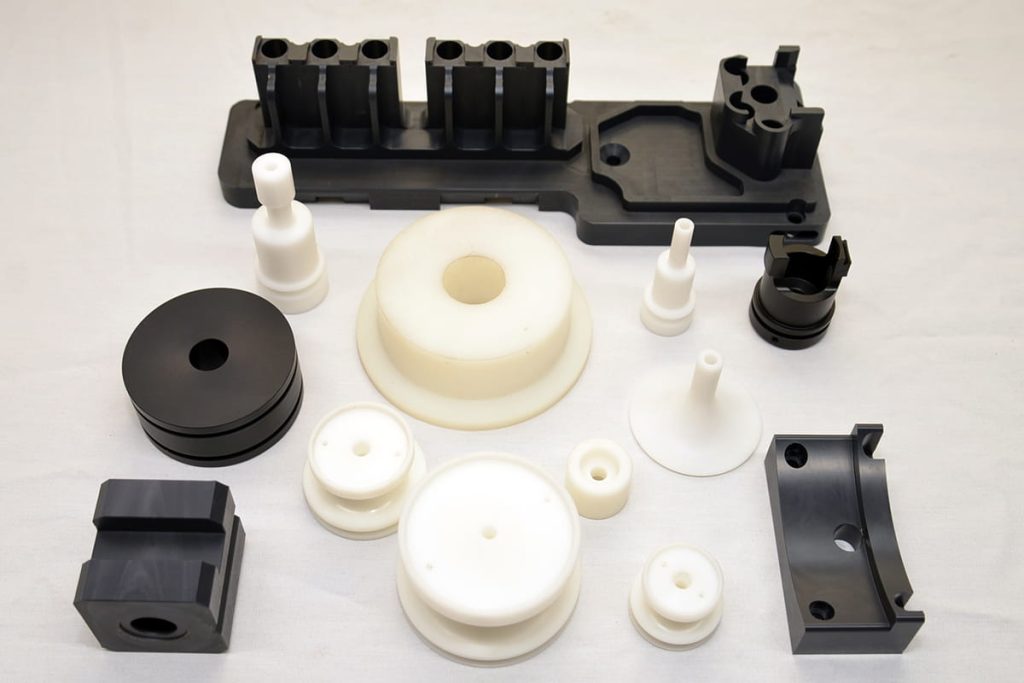

Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- HDPE

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- PTFE (Teflon)

- UPE

- Bakelite

- FR-4

CNC Milling Surface Finishes

Gain access to quality surface finishing for custom CNC milled parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Finishes for Plastic

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

Ready to start your next project?

Are you ready to start your next project? Tell the details or send CAD files for a competitive quote today.

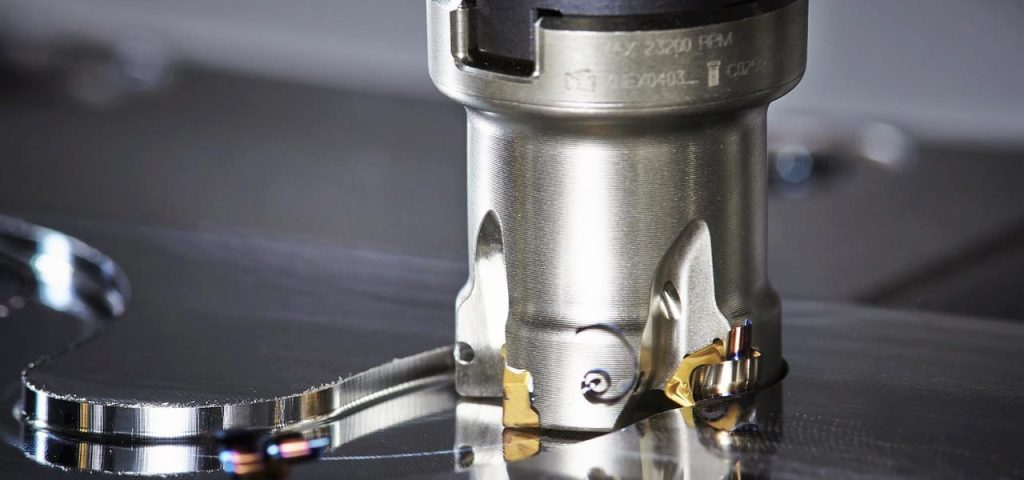

What is Milling?

The milling process uses rotating tools to remove material. While some tools such as drills, taps, and reamers can only plunge straight into the part, the most common cutter used on a mill is called an endmill. This tool not only cuts on the tip, but it can cut on the sides, allowing complex features to be machined.

A standard mill has 3-axis control. The X and Y axis move horizontally, and the Z axis moves vertically. Each axis can be controlled individually, such as for drilling or tapping where only the Z axis moves. They can also be moved simultaneously to make free-form contours. A common addition to a 3-axis mill is a 4th axis rotary indexer, which allows machining from more angles or machining the full perimeter of a cylindrical part.

Tolerances for CNC Milling

We are committed to precise measurement to provide our customers with consistent, high-quality results optimized for search visibility. Our standard tolerances for CNC milled metals are ISO 2768-m and for plastics are ISO 2768-c.

| Description | General Tolerance or Standard |

|---|---|

Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult Xtmadeparts’s Manufacturing Standards. |

Precision Tolerances | Xtmadeparts can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and GD&T callouts. |

Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

Threads and Tapped Holes | Xtmadeparts can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

Quality Assurance

- Material Inspection: We carefully verify the materials used for your project, ensuring they meet the desired quality standards and match your specific requirements.

- Skilled Workforce: Our experienced and highly skilled machinists and engineers closely monitor every step of the machining process, ensuring each part meets the desired tolerances and specifications.

- In-Process Inspection: Throughout the manufacturing process, our quality control team conducts regular inspections and measurements to detect and address any deviations or errors promptly.

- Final Inspection: Once the parts are machined and finished, our quality control team performs a thorough final inspection, checking dimensions, surface finish, and other required specifications. This guarantees that each part meets your expectations before shipping.

CNC Milling Design Guidelines

| Radii | Internal radii should be at least 1/3 of the cavity depth. Use larger radii whenever possible. |

| Threads and Tapped Holes | Diameter Φ 1.5-5 mm, depth: 3 times the diameter. Diameter Φ 5 mm or larger, depth: 4-6 times the diameter. Xtmadeparts can produce threads of any specification and size as required by the customer. |

| Minumum Wall Thickness | For metals: 0.8 mm; For plastics: 1.5 mm. Thicker walls ensure better structural integrity. |

| Text | CNC Milling: Minimum width of 0.5 mm and depth of 0.1 mm. Xtmadeparts can create standard text via CNC engraving or laser engraving as per customer requirements. |

| Holes | Minimum diameter of 1 mm. Hole depth should not exceed 4 times the diameter for best results. |

Industries

Our one-stop service helps designers verify their concepts at the prototype stage and transform their ideas into final products before launching them to the market. It can be widely used in many fields.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Request Your Free CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…