CNC Machining Services

Online CNC machining service for rapid prototypes and production parts in metals or plastics. Get instant quotes today, and order your custom CNC machined parts at a better price.

Precision and Speed for Your Most Demanding Applications

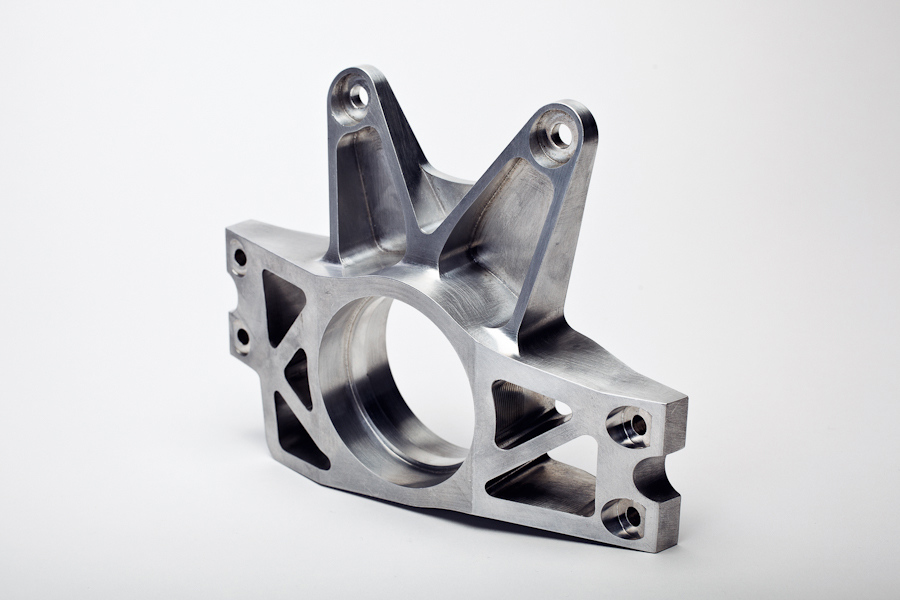

Do you have unique machining needs? Complex part geometry? Hard materials? Extremely tight tolerances? Xtmadeparts’ CNC machining services take on many challenging jobs every day because it is one of our core competencies.

If you are looking for a company that can meet your needs and lead your thinking and projects, now is the time to take a closer look at our comprehensive CNC machining services.

CNC Machining Solutions

Our advanced milling centers and turning equipment deliver precision with tolerances as tight as 0.001 inches. Beyond standard machining, we provide value-added services like CNC routing, EDM machining, and precision grinding, perfect for designers and product developers seeking to actualize innovative ideas with top-quality custom components. Whether the project is straightforward or complex, our equipped machine shops are ready to take it on. We guarantee not only superior quality but also rapid delivery—custom simple machined parts are shipped within just 1 day. Get started.

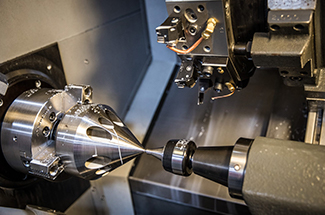

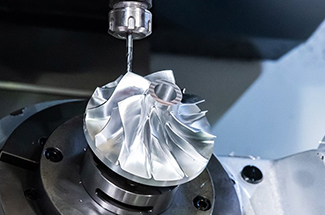

Our CNC Machining Capabilities

We are able to provide machining processes such as milling, boring, turning, threading, tapping, thread milling, knurling, profiling, reaming, facing, and more. Milling can provide parts up to 60 inches in length, 30 inches in width, and 30 inches in height. Turning can provide parts up to 28 inches in diameter and 48 inches in length, and bar feeds up to 12 feet long and 3 inches in diameter with very tight tolerances of .0005 inches. These processes are performed on 4-axis milling machines and 5-axis turning machines, using power tools, and all fixtures and tooling are provided in-house.

Ready to Get a CNC Machining Quote?

CNC Machining Materials

If you don’t know how to choose the right material, you can communicate with our engineer. He will recommend the right material for you based on your manufacturing needs and the performance of the CNC machined parts. We have prepared hundreds of material stocks to ensure that customers’ prototypes and small batches of precision CNC machined parts are produced within 24 hours. Some of our materials have been approved by IMDS. Material reports are available.

Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- HDPE

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- PTFE (Teflon)

- UPE

- Bakelite

- FR-4

Metals

- Aluminum

- Copper

- Brass

- Bronze

- Steel

- Stainless Stee!

- Magnesium

- Titanium

CNC Machining Surface Finishes

After the production of a part, tool marks may be visible on the workpiece. We offer a variety of surface treatment processes to achieve the desired surface effect on both plastic and metal parts after post-processing. Therefore, we can ensure that your parts meet both aesthetic and functional specifications.

Finishes for Plastic

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Our differentiated custom processing services

Rapid Prototyping

Rapid prototyping is the process of creating plastic and metal parts through CNC machining. It allows your design team to closely simulate the appearance, function, and material properties of the final product. In addition, testing components for fit and manufacturability helps validate and refine designs.

low-volume production

The benefits of CNC machining are particularly suited to low-volume production of custom parts. Its accuracy and repeatability, process flexibility, and wide range of material options help bring products to market faster. Whether you need a custom machined part or product, our CNC machine shop can provide integrated solutions to help you reduce production time.

Ready to start your next project?

Are you ready to start your next project? Tell the details or send CAD files for a competitive quote today.

What is CNC machining?

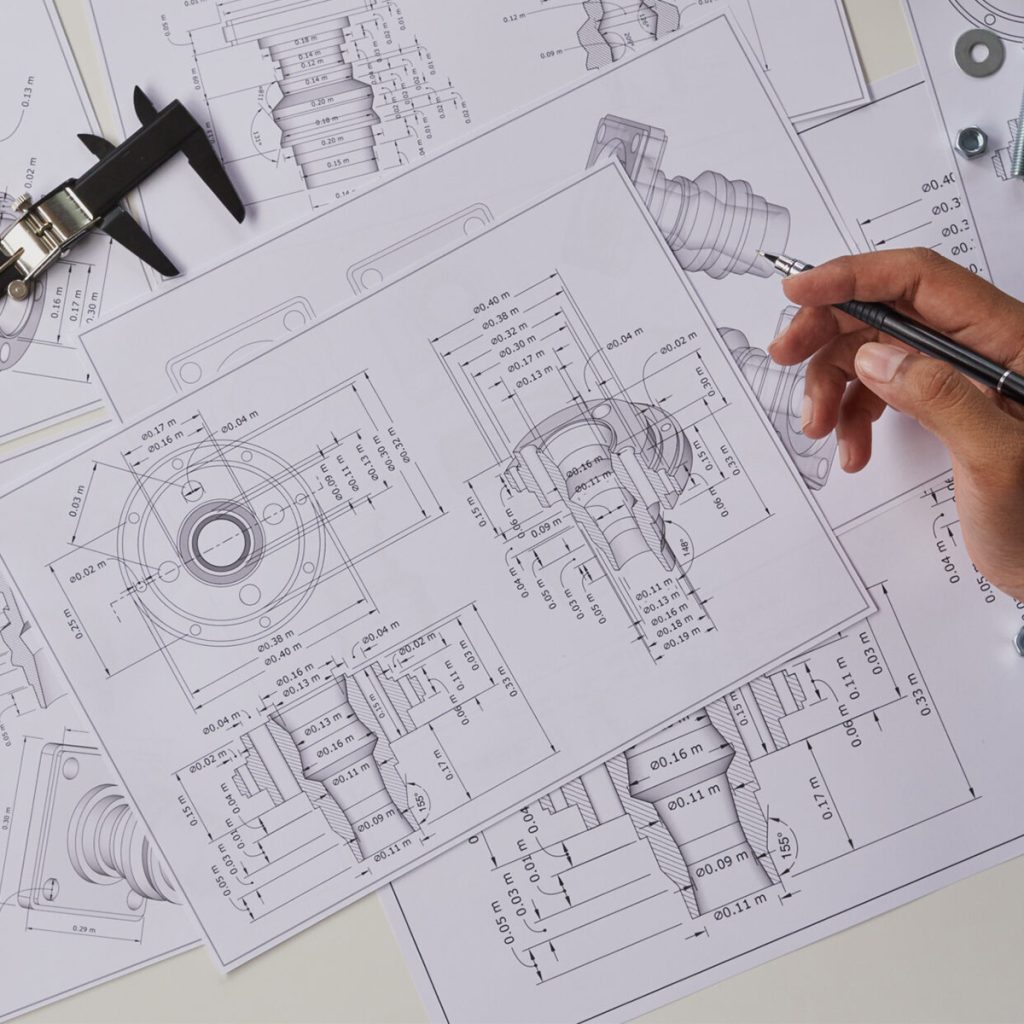

Computer numerical control (CNC) machining is a manufacturing process that uses automated high-speed cutting tools to remove multiple layers of material from a stock piece (called a blank or workpiece) to produce a custom designed part. Standard CNC machines include 3-5 axis mills, lathes, and routers. Design engineers provide CAD (computer-aided design) models to skilled CNC machinists and programmers who convert the models into CAM (computer-aided manufacturing) software. With the right programming, the machinist can set up a CNC mill or lathe to complete most of the steps required to make a part. The CNC machine is given a specific set of instructions and uses those instructions to cut a part from the blank. CNC machine instructions are given in the form of computer code. The code tells the machine where to place the tool head, how fast the tool head should rotate, and the coordinates to which the tool head will move. The machine then automatically produces the final part of the design drawing.

Design Guidelines for CNC Machining

Learn the practical guidelines listed below to optimize your design for manufacturability. Send us a drawing file at [email protected] and our experts will provide feedback on your custom machined part to achieve the best results in CNC machining.

| Radii | In CNC machining, sharp internal corners on a workpiece will naturally form rounded corners (radii). The depth must not exceed 12 times the diameter of the drill. For end mills, the depth must not exceed 10 times the diameter of the tool. |

| Threads and Tapped Holes | Diameter Φ 1.5-5 mm, depth: 3 times the diameter. Diameter Φ 5 mm or larger, depth: 4-6 times the diameter. RapidDirect can produce threads of any specification and size as required by the customer. |

| Undercuts | Square profiles, full radius, dovetail profiles. |

| Text | CNC Milling: Minimum width of 0.5 mm and depth of 0.1 mm. CNC Turning: Xtmadeparts can use laser marking to create standard text for CNC turned parts. Xtmadeparts can create standard text via CNC engraving or laser engraving as per customer requirements. |

Alternatives to CNC Machining Services

While a CNC machining service is appropriate for creating many types of parts, it does have some limitations. For example, it can’t be used to create internal features such as internal cavities or conformal cooling channels. These are easily made using additive manufacturing methods like DMLS.

For certain types of flat workpieces, laser cutting, water jet cutting, wire EDM cutting, photo chemical etching or metal additive manufacturing may be more efficient.

Advantages Of CNC Machining Services

No matter what material you use, you need absolute confidence that it conforms to your specifications and regulatory requirements. That’s why we have a best-in-class material testing laboratory. We use positive material identification (PMI) to verify all incoming stock, and provide you with a full physical analysis. It’s the only way to be sure you get exactly the quality and performance you demand.CNC machining offers many advantages for product developers, including:

- Fast material removal

- Tight tolerances and high precision

- Excellent for making complex geometries

- Versatile

- Suitable for many different kinds of substrates

- Unlimited volumes

- Low investment in tooling

- Fast turnaround

- Parts are full-strength

- Excellent surface finishes

- Easily customized

Industries We Serve

Xtmadeparts’ CNC machining services cater to a variety of industries, ensuring that the unique needs of each industry are precisely met. Therefore, it has been recognized by global clients from different industries.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Request Your Free CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…