Medical Industry

We are the Medical Parts Experts. Manufacturing medical parts requires tighter tolerances and unique materials. Xtmadeparts has state-of-the-art equipment, knowledgeable staff, and strict controls that make us stand out in the field of precision medical machining.

Helping you innovate, design and manufacture medical devices

Do you need a professional custom parts manufacturer to manufacture medical devices? As medical devices and instruments become more complex, manufacturers in the medical industry rely on precision medical machining services to produce more parts. The detailed design specifications and tight tolerances of these parts are critical to the success of medical staff and the health of patients. Therefore, our engineers and production personnel will carefully check the drawings and processing details at every process step, from prototypes to small batch production to large-scale production. During the prototype stage, customers usually continue to optimize the drawings, and ignoring these details is unforgivable for our company’s management. Ensure that customers receive standardized parts that meet their needs every time. This is the perfect solution for your medical manufacturing needs.

From Prototyping to Full Production Capabilities

Xtmadeparts understands that successful products and customer relationships are the result of creativity in designing for manufacturability, the ability to deliver tight tolerances, and expertise in gaining insights from an iterative process. Our engineers work with your design team on the manufacturing of medical device parts, and our knowledge and experience with FDA regulatory requirements can bring immediate value to our relationship.

During the prototyping phase, we begin by producing several sample parts to assist your design engineers with proof of concept. We then assist with iterations during the prototyping phase, responding quickly to design changes. We can complete the necessary on-the-fly changes to bring your customers’ new products to market faster. We work directly with your design engineers to evaluate machinability and material selection to avoid potential quality issues. So when your precision medical device design is ready for clinical trials and FDA or other regulatory approval, we begin building robust processes and documentation that will play an important role in the future success of your product. Finally, we focus on continuous improvement of our internal management processes to reduce costs and lead times, which can have a positive impact on the quality of the parts we provide to you. Once market approval is obtained, we are able to handle high-precision, close-tolerance, and high-volume part machining to meet your monthly and annual needs.

Medical Manufacturing Services

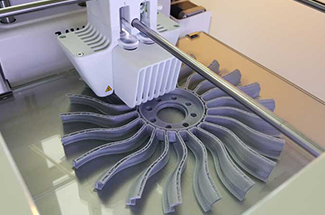

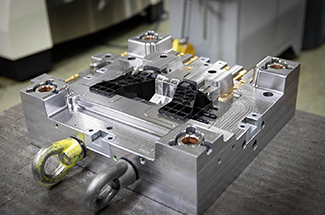

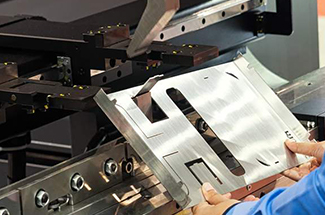

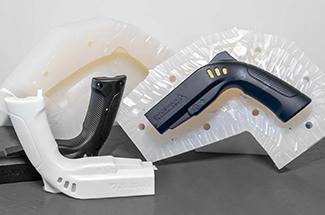

Provide rapid prototyping and low-volume production services, providing precision manufacturing services for medical devices and parts. Through creative and agile manufacturing technologies such as 3D printing, injection molding, polyurethane casting, and precision CNC machining, we accelerate innovation, expand manufacturing scale, and streamline the medical supply chain. This enables us to meet the rigorous and unique needs of the health and fitness industry.

CNC Machining

3D Printing

Injection molding

Sheet Metal Fabrication

Vacuum Casting

Rapid Tooling

Intellectual Property Protection

The security of the intellectual property and technology of customized parts is an aspect that cannot be ignored, as it may involve sharing ideas and sensitive information with partners who attach great importance to confidentiality agreements. In the customized parts in the medical field, signing a confidentiality agreement is a common means to protect the interests of customers. Xtmadeparts will sign the agreement, promising not to disclose confidential information of customer products without the customer’s permission.

Benefits of Precision Machining for the Medical Industry

Precision machining offers many benefits in the medical industry, from the production of surgical instruments to the manufacture of prosthetics and medical implants. The ability to produce complex and high-precision parts with tight tolerances is essential to ensure the proper fit and function of medical devices and equipment. Using custom machining services to manufacture related products in the medical industry is essential to improving patient outcomes and advancing the field of medicine.

One of the main benefits of precision machining services in the medical industry is the ability to produce parts with extreme precision and repeatability. This is especially important in the production of medical implants and prosthetics, which must be designed and manufactured to very precise specifications. The repeatability of custom machining services also allows for the production of multiple identical parts, ensuring consistent performance and reliability.

In addition to precision and repeatability, precision machining also improves the efficiency of the manufacturing process. It uses advanced technology and automation to produce parts quickly and accurately, thereby reducing manufacturing time and cost. This is especially valuable in the medical industry, where time is often critical and cost is a major concern.

Ready To Start Your Next Project?

Material Compliance

Materials for medical applications need to ensure that the materials meet regulatory standards such as biocompatibility and sterilization compatibility. There are also many medical device components whose materials must comply with FDA, ISO and other relevant medical standards. We have domestic material supplier channels that meet safety standards. For special materials, we also import raw materials from Europe and the United States to meet customer product requirements and provide material certification reports to ensure that there are no material problems with the parts we produce.

Materials suitable for medical applications

- Titanium

- Stainless steel

- Silicone

- Inconel

- Nylon

- ABS

- TPE

- Silicone

- POM

- PEEK

- PC

Surface finishing for the medical industry

We can provide a variety of high-level surface finishes. The following are the common surface finish options we use, please contact us if you need more surface finish options.

- As machined

- Sanding & Polishing

- Sand, Bead Blasted

- Painted

- Powder coat

- Anodized

- E-Coating

- Nickel Plating

- Chromed

- Zinc Plating

- Chromate Conversion Coating

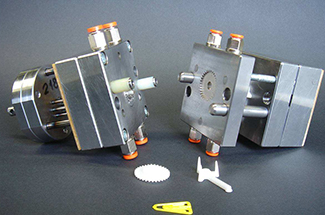

Medical parts we can manufacture

Our extensive production capabilities can meet the needs of many healthcare applications.

- Prototypes

- Anatomical models

- Replacement parts

- Surgical instruments

- MRI and X-Ray components

- Monitoring equipment components

- Tables and panels

- Medical carts

- Physiotherapy apparatuses

- Electronic equipment components

- Prostheses

- Medical delivery systems

- Fluid management systems

- Biotechnology components

- Respiratory devices

- Handheld devices

- Diagnosis equipment

- Ultrasonic equipment

- Care equipment

Our Customers

- Medical device manufacturers

- Healthcare providers

- Life sciences

- Biotechnology corporations

- Pharmaceutical companies

- Diagnostics equipment manufacturers

- Surgical and medical instrument manufacturers

- Surgical appliance manufacturers and suppliers

- Hospital operators

Ready to get started?

If you are a medical device manufacturer or are engaged in the manufacture of medical components, we are responsible for providing solutions for your component manufacturing.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…