Energy

Xtmadeparts advances manufacturers in the energy sector, including oil, gas, solar, wind and hydroelectric, by developing and integrating the world’s best precision parts machining solutions, including turnkey automation and custom application engineering services.

Custom Energy Parts Machining Company

Our company is a leader in providing cutting-edge custom parts machining services to the renewable energy industry, delivering solutions tailored to the unique needs of this rapidly growing industry. We specialize in producing essential components for wind turbines, solar and hydroelectric systems, and wave energy, ensuring they meet the highest standards of precision and reliability.

We utilize advanced manufacturing techniques and a team of dedicated professionals to produce parts that increase the efficiency and lifespan of renewable energy systems. By providing durable, high-performance components, we contribute to the sustainability and growth of clean energy solutions, solidifying our position as a trusted partner in the renewable energy supply chain.

Comprehensive Machining Solutions for Precision Parts and Components for the Energy Industry

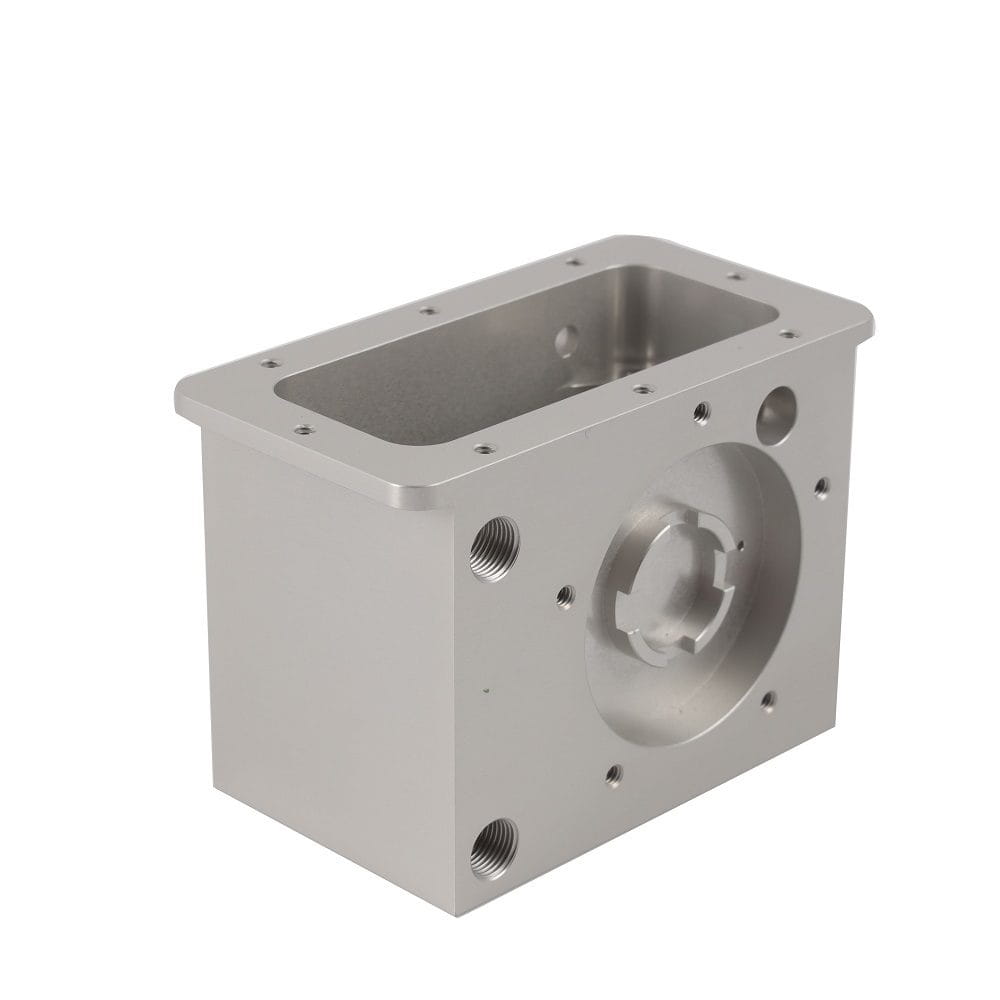

The energy industry continues to grow rapidly, with high demand for a wide range of equipment that requires precision-machined and durable parts or components to harvest fossil fuels, solar, hydro, wind, and more. Components manufactured for drilling rigs, hydraulic fracturing equipment, refineries, wind turbines, and solar panels often require durable materials and tight tolerances. CNC machining technology is a useful and effective way for the energy industry to build these systems and make quick repairs using precision-machined parts.

Xtmadeparts provides comprehensive machining solutions for the energy and renewable energy industries, with precision-machined parts and components that operate reliably in challenging environments such as highly corrosive and abrasive conditions. Our team of engineers and machinists have extensive experience in manufacturing replacement parts for refineries or mass-producing precision components for solar panels. They will work with you to guarantee the production of the highest quality energy and power components and exactly meet the specifications of your project. From wind and solar to hydro turbines, components for the energy industry are manufactured with the finest materials and tightest tolerances, so you can count on us for the best results.

Our Manufacturing Services

Xtmadeparts offers top-notch manufacturing capabilities, perfect for rapid prototypes and custom production orders. Our self-owned factory and extensive Chinese manufacturing network are equipped to deliver complex, and quality parts efficiently.

CNC Machining

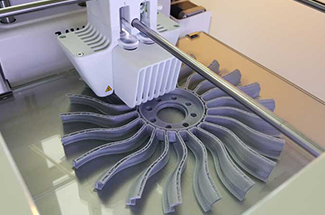

3D Printing

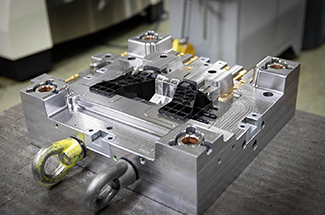

Injection molding

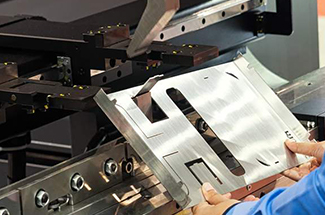

Sheet Metal Fabrication

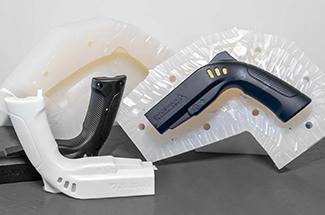

Vacuum Casting

Rapid Tooling

Already initiated and ready to start your project?

Speak with an expert in the energy and power generation industry today! Our team is standing by and ready to answer questions or provide a quote for your project.

Engineering Excellence

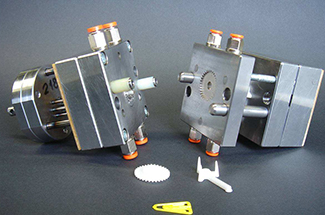

Xtmadeparts manufactures and assembles metal and plastic components. We clean, inspect and deliver them ready for assembly for immediate use. This speeds up the development cycle of new products and translates into reliable production.

Our customers consider Xtmadeparts to be a smart addition to their design teams because our innovative engineers are able to help solve problems. We often work in tandem with design engineers and collaborate with scientists and researchers in the early design stages.

Xtmadeparts develops prototypes to test hypotheses and understand what changes and adjustments must be made to do something new and bold in existing and emerging energy industries.

Nuclear Power Plant Fabrication

At Xtmadeparts, our nuclear power plant fabrication services are second to none. We offer a wide range of components to meet stringent international standards. We can produce fine and specialized parts using state-of-the-art equipment and specialty materials designed specifically for nuclear power equipment.

Our extensive experience in the energy industry gives us insight into how to manufacture the safest, most reliable precision components for nuclear power plants. We understand the special demands of heavy fabricated component production and the necessity for just-in-time production of industry-specific custom machined parts.

Our Quality Management System (QMS) is certified to AS9100 and ISO 9001 standards, and we have implemented additional requirements in compliance with ASME NQA-1 to ensure your nuclear components meet or exceed industry standards. We also conduct in-depth and comprehensive inspections on every part or component produced and assembled at our facility to ensure the highest quality products and industry compliance.

Available Materials for Energy Parts

We have a team of highly skilled engineers who specialize in manufacturing a wide range of parts for the energy industry. They have the expertise to manufacture parts from a wide range of materials based on your preference and application. If you have a specific material you would like us to use, please contact us.

- Metal: Alloy Steel, Brass, Mild Steel, Plastic, Stainless Steel, Monel, Nylon and Thermoplastic, Aluminum,Titanium,Copper,Nickel-Based Super Alloys,etc.

- Polymers: ABS, Acrylic, Acetal, Delrin, POM, Nylon, Polycaprolactam, PC, Polycarbonate, PEEK, Polyether ether ketone, PEEK Glass-Filled, PP Polypropylene, PTFE, Teflon, PVDF, UHMW PE, Ultra-high-molecular-weight polyethylene, Custom polymers are also available.

Surface finishing options

We recognize the importance of combining high-quality parts with an aesthetically pleasing finish. To meet this need, we offer a range of finish options that enhance component performance. These finishes are not only decorative, but in some cases they also provide functional benefits. The following is a list of finish options available for components in the Energy and Power industries:

- Plating

- Anodizing

- Passivation

- Heat Treatment

- Laser Engraving

- Painting

- Oxidation

- Chromate

- Electroplating

- Insert Installation

- Polishing

- Brushing

- Texturing

- Powder Coating

Energy Industry Applications

The energy industry requires high precision and strict adherence to specifications during manufacturing. Whether it is solar, wind or hydro, large parts and components need to be rugged and durable in harsh working conditions. We are ready to meet the challenges of various energy sources, including commercial electricity, solar, fossil fuels, oil and gas, with comprehensive manufacturing solutions to improve overall product quality and cost efficiency. Some of the energy components we manufacture include:

- Gearboxes

- Jigs and fixtures

- Flowmeter parts

- Generator parts

- Quick repair tools

- Pilot testing parts

- Sand control screens

- Hangers

- Turbine blades

- Pump manifolds

- Drill rig components

- Nozzles and flow meter parts

- Engineering test pieces

- Flowline components

- Wind and water turbines

- Blades, rotor parts, and fans

- Impellers, pipelines, and pipe centralizers

- Power stations and transformer components

- Gears and shafts (ram shafts, locking shafts, and bonnets)

- Enclosures and sealing accessories for explosives and perforating

We look forward to working with you on your next energy project

Get advanced energy industry parts machining solutions to grow your business.

Latest News

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…