Consumer Products Industry

Our team of experts works closely with customers on all projects to optimize design, material selection and manufacturing to meet specific application requirements. Taking into account our customers’ cost and time requirements, we can transform the crudest ideas into refined, durable consumer parts.

Best Consumer Product Contract Manufacturing Supplier

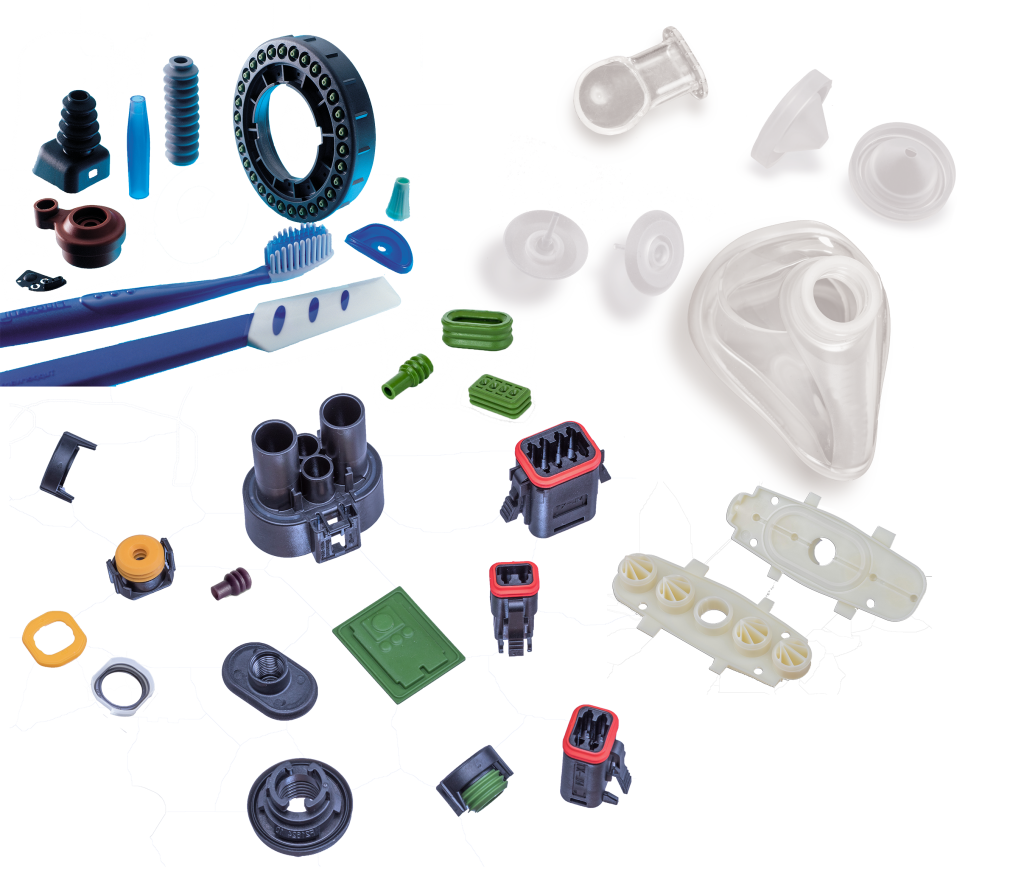

Xtmadeparts manufactures parts and assembles any consumer product with plastic components. We provide plastic injection molding and value-added services including complete manufacturing, assembly, tooling, decorative applications, packaging, kitting, printing and creative design, all delivered on time.

With our state-of-the-art production machines, experienced technicians and strict quality control guidelines, we manufacture custom industrial control components with unmatched precision and quality. Our certified quality management system ensures dimensional compliance and guarantees reliable and dependable components. What sets us apart is our engineering expertise and collaboration, backed by years of industry experience. We provide fast response and prototyping, customer-centric solutions, and comprehensive services.

Build and test faster with on-demand manufacturing solutions for consumer products

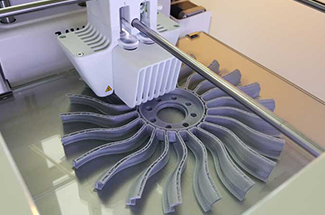

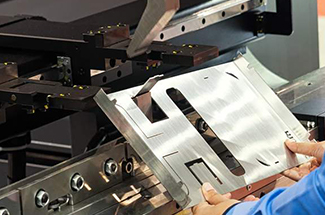

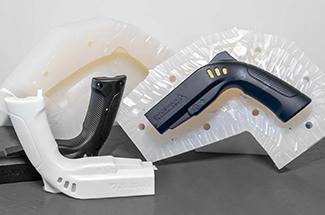

Development speed, accuracy and user-centric design optimization are at the core of the consumer goods industry. Therefore, the time to design, test and manufacture prototypes should be as short as possible. At Xtmadeparts, you can now speed up your product development cycle, from design to first build, prototype and final part manufacturing! Because we have perfected the process of combining multiple manufacturing options with a wide range of raw materials to create finished parts that are both functional and beautiful in the shortest possible lead time. Our holistic management system is particularly suitable for designers and companies who want to expand their SKU and product range, because there is no need to invest high capital costs for rapid prototyping, small batch units and rapid market testing.

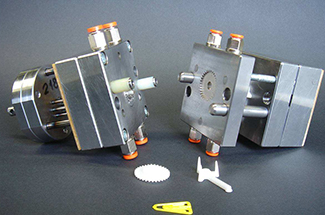

Consumer Goods Manufacturing Solutions

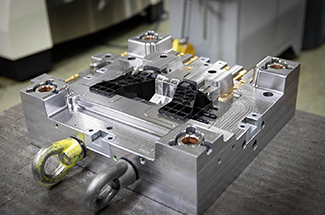

Our processes utilize state-of-the-art manufacturing techniques to provide our customers with the highest quality products. Whether you require a complex or simple manufacturing process, our skilled team can provide solutions to meet a variety of consumer product needs.

CNC Machining

3D Printing

Injection molding

Sheet Metal Fabrication

Vacuum Casting

Rapid Tooling

Providing full-service capabilities and streamlined processes to help you from prototyping to packaging

In the consumer marketplace, trends change rapidly, so we provide valuable industry insights and innovative, cost-effective solutions to help you keep up. We understand that the beauty and design of a product can have a profound impact on its success, so we provide wholesale, private label and custom product solutions that go beyond the ordinary. Our team of design engineers specializes in creating one-of-a-kind custom solutions for parts in high volumes to ensure your brand stands out in a competitive market.

Ready to Get a Quote for Consumer Products?

Our experts have experience in providing innovative solutions at every stage of product development, from product design to production.

Consumer Goods Components We Produce

Our expertise covers a wide range of consumer goods and components, meeting the diverse needs of different markets.

- Containers

- Vessels

- Wells

- Pans

- Insets

- Covers

- Lids

- Caps

- Housings

- Panels

- Chambers

- Cans

- Pots

- Canisters

- Basins

- Reservoirs

- Receptacles

- Trays

- Inserts

- Shields

- Enclosures

- Frames

- Sinks

- Tanks

Materials

We offer a wide range of materials including metals, plastics and composites.

Metals

- Carbon steel

- Stainless steel

- Aluminum

- Magnesium

- Zinc

- Iron

- Gold

- Silver

- Copper

- Brass

- Tin

Plastics

- Polyamides (Nylon)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyesters Polycarbonates Acetals

- Thermoplastic Elastomers

- Thermoplastic Polyurethane

- Polysulphone

- Polyarylates Polyamide Imide

- Polystyrene

- High & Low-Density Polyethylene

- Polypropylene

Surface Finishing Services

We offer a variety of different surface treatments and coatings for plastic and metal prototype and production parts. Most parts, whether produced by additive manufacturing, polyurethane casting, injection molding, or machining, require a special process or coating surface treatment before they can be prototyped or produced.

Plastic Part Finishes

- Vacuum metalizing for metallic-like finishes, like chrome

- Plating for metallic finishes with nickel, chrome, copper, gold, and more

- Painting custom colors with our in-house Sherwin Williams color match system

- Color-matched colorants, compounds, and materials

- Anti-static nickel coatings

- Soft-touch coatings to simulate over-mold grips

- Vapor polishing (or vapor smoothing)

- Dyeing

- Tumbling

- Bead blast

- 3D-printed textures

- Molded-in textures (urethane and injection molding)

- Painted finishes: textured, matte, gloss

- Part decorations (including labeling, silk screening, and pad printing)

Metal Part Finishes

- Heat treat

- Fluorescent penetrant inspection (FPI)

- Magnetic particle inspection (MPI)

- Passivation

- Plating for metallic finishes with nickel, chrome, copper, gold, and more

- Painting custom colors with our in-house Sherwin Williams color match system

- Powder coating

- Anodizing

- Laser marking and engraving

Our customers

- Consumer electronics makers

- Appliance manufacturers

- Personal and household goods manufacturers

- Food and beverage companies

- Alcohol companies

- Athletics equipment manufacturers

- Toy manufacturers

Ready to start your next project?

Our in-house capabilities are ideally suited for the fast-moving consumer goods industry. On-demand manufacturing and volume flexibility also means we’re ready to work with you to produce one, 10,000, or anything in between, with no minimum order quantity.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…