Aerospace Industry

Our team of technical experts confidently tackles the most challenging aerospace projects. Regardless of the design requirements or production volume, Xtmadeparts is committed to working closely with our customers to do our utmost to provide quality products that exceed expectations.

Turnkey Assemblies for Aerospace Projects

Our aviation machine shop has the resources to supply turnkey components, and we have established a strong supplier network within the industry to fully support our customers’ needs. As a professional manufacturer of custom aerospace parts, Xtmadeparts’ engineers and production team have more than ten years of experience in machining precision components, and our internal management emphasizes competitive pricing, on-time delivery and excellent customer service. We produce the simplest or most complex parts based on our customers’ unique specifications using a variety of materials ranging from easy-to-machine materials to difficult-to-machine high-temperature super alloys.

Aerospace Prototyping and Manufacturing with Xtmadeparts

Producing reliable aerospace part prototypes is a task that relies on accuracy, quality and strict adherence to specifications. With a focus on aerospace prototyping, we have accumulated expertise in producing a wide range of aerospace parts, whether simple or complex. We perform extensive quality checks and tests to ensure that all parts produced must satisfy our customers and undergo the most stringent certification and testing procedures.

Aviation Parts Manufacturing Service Types

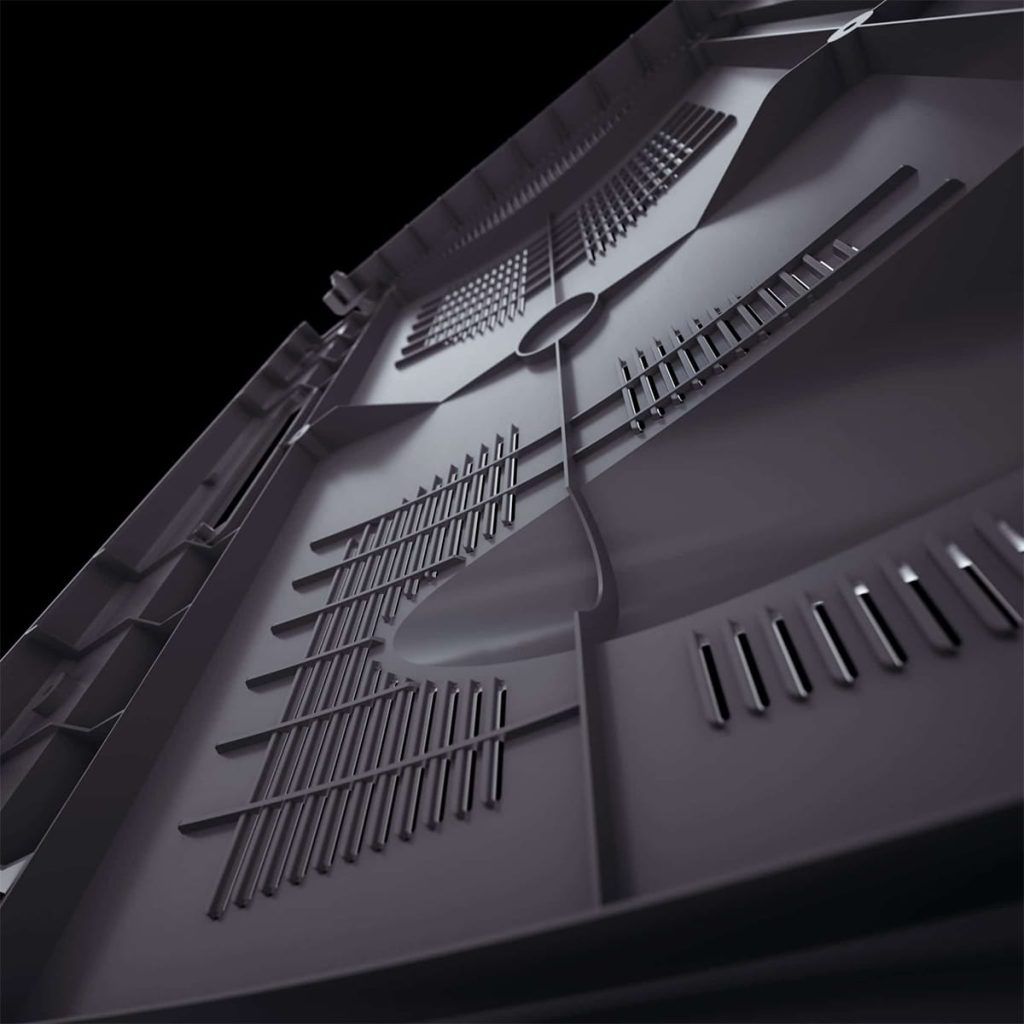

We specialize in the manufacture of difficult and complex aerospace parts. Our unique process ensures that every aspect of a project is fully understood and perfectly executed. You can be assured that our aerospace parts manufacturing process will meet your expectations and adhere to the highest quality standards. We hold every member of our team personally accountable to produce the best parts for our customers.

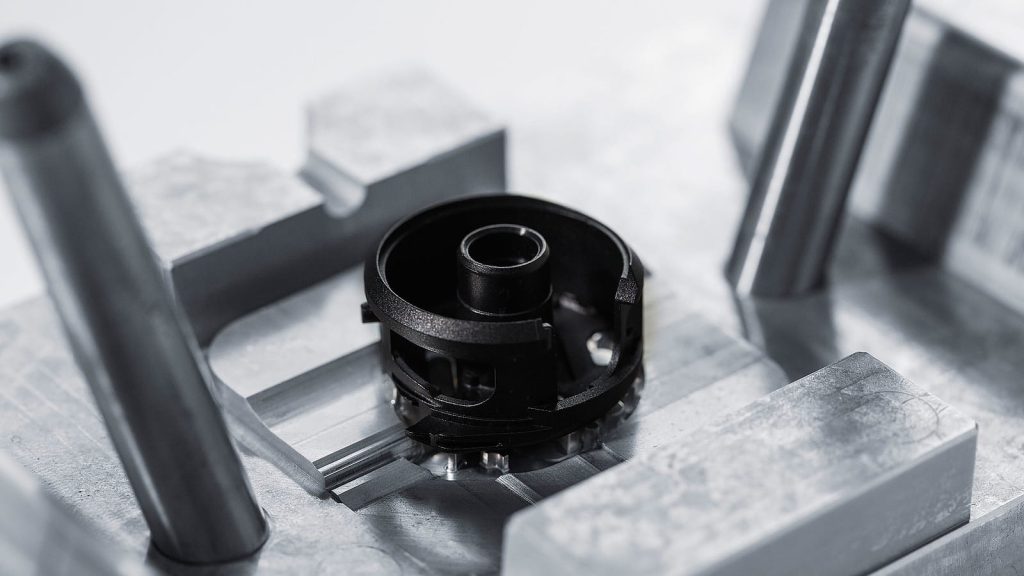

CNC Machining

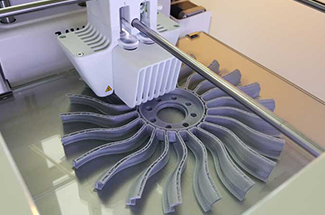

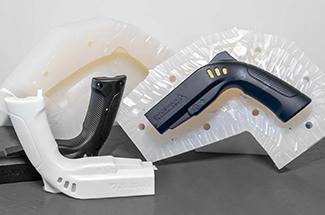

3D Printing

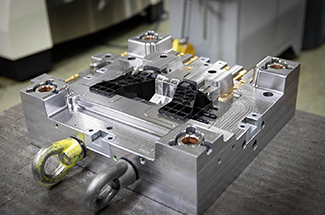

Injection molding

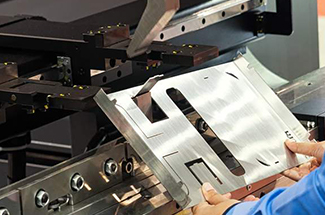

Sheet Metal Fabrication

Vacuum Casting

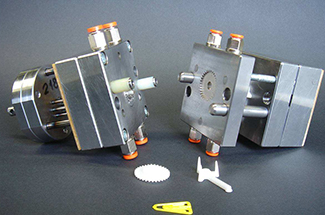

Rapid Tooling

Precision Machining Facility Produces OEM Parts for Aerospace Engineering Companies

As the aerospace industry expands, the demand for precision machined parts continues to increase as aerospace engineers build commercial, military, and private aircraft capable of flying higher and faster, and aerospace engineers demand ever-higher precision in spacecraft and satellite components. Manufacturers of these types of components rely on OEM parts with the tightest tolerances to fit complex subsystems for satellite platforms, spacecraft structural components, or propulsion systems.

Since its founding, Xtmadeparts has continued to advance with evolving aerospace technology. Our temperature and contaminant controlled custom machining facilities allow us to produce high-end OEM components for the most complex applications. The aerospace industry is always advancing, and our team is committed to keeping up. Whatever the task at hand, our creative professionals are up to it.

Benefits of Precision Machining for the Aerospace Industry

The aerospace industry covers a variety of activities such as the design, development, and production of aircraft, as well as the maintenance, repair, and modification of aircraft. It also involves the manufacture of aerospace components and systems such as engines, avionics, and landing gear, as well as the launch and operation of satellites and spacecraft and the development and utilization of space technologies. Precision machining can manufacture parts with tight tolerances, which is essential to ensure the proper fit and function of aircraft components. In addition, it can form complex geometries, thereby enhancing the versatility and functionality of aerospace products. High-quality, reliable parts produced through precision machining help improve the performance and reliability of aircraft. The repeatability of the manufacturing process helps in the efficient production of multiple identical parts. In addition, precision machining can improve cost-effectiveness and minimize waste due to the use of advanced technology and automation in the manufacturing process.

Ready to start your next project?

Contact us and send us the CAD file of your part design and our engineers will contact you within 24 hours with a quote.

Materials

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Plastics

- PVC

- Nylon

- Delrin

- PTFE

- UHMW

- Ultem

- PEEK

- Acetal

Surface Finishing

We offer a wide range of high-level surface finishes. We have listed only some of the common surface finish options. There are many more surface finish options for custom parts for the aerospace industry.

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

Customers we serve

- Aircraft manufacturers

- OEM component manufacturers

- Aircraft infrastructure companies

- UAV manufacturers

- Aircraft maintenance and service engineering companies

- Aircraft design studios

- Spacecraft manufacturers

- Avionics companies

- Aftermarket parts suppliers

- Defense and military companies

- Aerospace engineering centers

- Space shuttle companies

- Regulatory and aviation authorities

We manufacture parts for the aerospace industry

Aerospace often requires thousands of large and small heavy components to produce aircraft. Such components must be manufactured within tight tolerances to withstand harsh environments, including exposure to extreme temperatures, contaminants, and varying atmospheric pressures. The various parts we manufacture are listed below.

- Engines

- Fuse bodies

- Turbines

- Screws and other fasteners

- Tire parts

- Brakes

- Electrical components

- Radar systems

- Air conditioning systems

- Vacuum pumps

- Fuel pumps

- Lighting systems

- Wing supports

- Night vision devices

- Transmission components

- Instrument panels

- Helmets

- Unmanned aerial vehicles

- Gears

- Teaching aids

- Protective equipment

- Fastenings

- Frames, handles, stands

- Chassis and housing

Your preferred aerospace parts custom machining company

Don’t let supply chain issues bother you. We are here to provide you with the high-quality machining capabilities you need.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…