Metal 3D Printing

Metal 3D printing enables the cost-effective production of high-mix, low-volume metal parts. It also allows you to create complex part designs that are impossible using traditional methods, without compromising design, quality or performance.

The Next Frontier in Manufacturing

Metal 3D printing services enable on-demand printing of metal parts by eliminating some of the upfront costs. Parts can be produced quickly, so it changes the way rapid prototyping is done, quickly iterating part designs to test part fit, surface finish, and functionality. It enables designers to simplify assembly and create part designs that cannot be machined or cast. It can even be used for transitional production until production tooling is complete.

We help companies create unprecedented results with metal 3D printing

We are a leading provider of full-service metal 3D printing solutions, and we are committed to helping you throughout your metal 3D printing journey. Our metal 3D printing technology and rich material selection make us stand out in the market, and our experienced consulting and application engineering team will help your organization succeed in metal 3D printing, providing support for your organization from metal 3D printing prototypes to full production.

Our dedicated and solution-oriented staff has extensive experience in part manufacturability analysis, part manufacturing, and project delivery, while working closely with customers to understand the most appropriate level of service required for their applications. We have a well-trained and excellent team with diverse expertise. And we continue to invest in our people, technology, and equipment to be able to quickly and innovatively solve complex needs. Our company culture is further enhanced by the deployment of internal management systems that save time and reduce costs, and knowledgeable and talented people who work for you.

Metal 3D Printing Process Types

We offer a variety of metal 3D printing process types, giving you complete design freedom to create stronger parts that are lighter, more durable, and perform better.

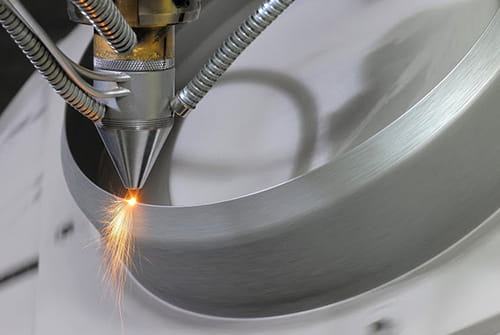

Selective Laser Melting (SLM)

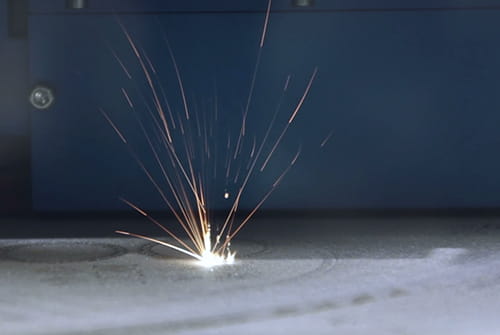

Electron Beam Melting (EBM)

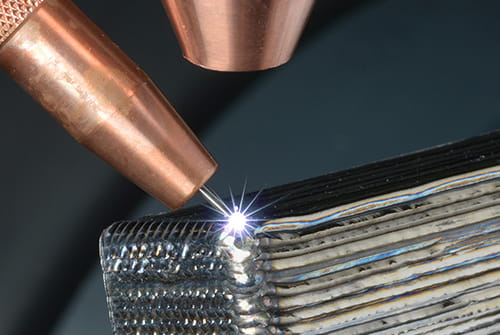

Laser Deposition Welding (LMD)

Metal Powder Application (MPA)

Our Large 3D Metal Printing Capabilities

Save time, reduce direct and indirect costs, explore more possibilities and operate at higher efficiencies than traditional manufacturing operations by using our large 3D metal printing technology to produce your next large part. Our printers can produce large, complex parts up to 500mm x 500mm x 500mm on an industrial scale. Whether you are looking for a custom part or a regular production part, we have you covered.

We are uniquely positioned in this space to provide the right experience and technology for your project based on your material and application requirements. We can draw on our extensive equipment and expertise to meet your needs. Every step is customized to provide the best material, design and end product for your specific application. Every conversation is a collaboration between our team and yours. Every result is designed to meet the needs of your operation.

Popular Materials

We offer a wide range of metal 3D printing materials, each of which meets the highest quality and performance standards. With years of experience, we offer a wide range of options to make your creative dreams come true, ensuring durability, precision and excellence in every print.

- Stainless steels

- Tool steels

- Titanium alloys

- Aluminum alloys

- Nickel-based superalloys

- Cobalt-chrome alloys

- Copper-based alloys

- Precious metals (gold, silver, platinum…)

- Exotic metals (palladium, tantalum…)

Post-processing options for metal 3D printed parts

The strength, dimensional accuracy, and appearance of the final metal part can be improved using a variety of post-processing processes.

Secondary Processing

- 3- and 5-axis milling

- Turning

- Polish (Mirror or Brushed)

- Passivation

- Wire EDM

- Tapping and reaming

Finishing

- Abrasive Blast (Grit & Ceramic)

- Shot Peen

- Optical Polish

- Electrochemical Polishing

- Abrasive Flow Machining

- Electroplating

- Micro Machining Process (MMP)

Heat Treatments

- Stress relief

- NADCAP heat treatment

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Mechanical Testing

- Tensile

- Rockwell Hardness

Powder Analysis & Material

- Traceability

- Chemistry

- Particle size and distribution analysis

Ready to get started on your custom metal 3D printing quote?

How does metal 3D printing work?

The 3D printer begins sintering each layer, first the support structures onto the build plate, then the part itself, using a laser to align the metal powder bed. After micro-welding the cross-section layer or powder, the build plate moves down and a recoating blade moves across the platform to deposit the next layer of powder into the inert build chamber. The process repeats layer by layer until the part is complete.

Design Considerations for Metal 3D Printing

While it opens up endless possibilities for creating complex designs, there are still some factors to keep in mind when designing for metal 3D printing. These factors include:

- Identify the critical dimensions of the part and ensure they are flat or parallel to the print bed

- Maximize part-to-bed contact

- Design with fewer supports

- Avoid overhanging structures.

Benefits of Metal 3D Printing

Mass Customization

All possible variations of a certain design can be prined at once to determine the best functioning design among them. Finds application in new product development parts.

Monolithic Design

Multiple assembled components can be redesigned as a single part and then printed, which increases the life cycle of the part. This benefit finds application in dynamic parts.

Improved Functional Performance

3D printing helps to improve the efficiency of a component as the design is based on functionality rather than design based on manufacturability. This finds application in die and molds.

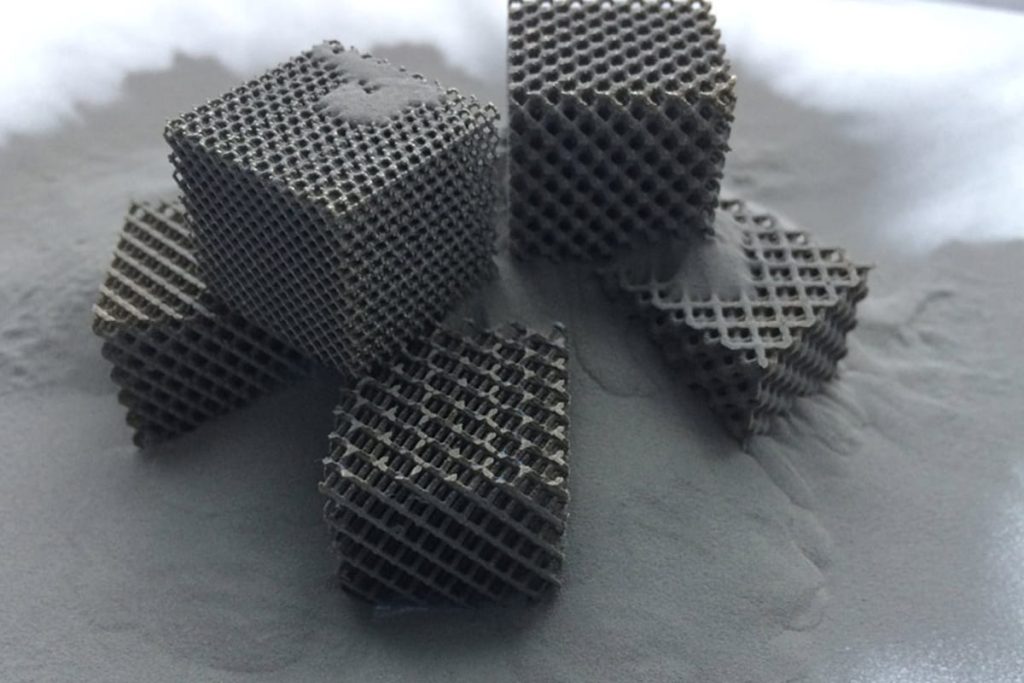

Weight Reduction

The process allows for printing parts with lattice structures which reduces the part weight while maintaining the required strength as well. Finds application in aerospace & space components.

Industries We Serve

Metal 3D printing is changing the way many high-value industries use metal manufacturing. It can provide a faster production method for manufacturing metal parts in a variety of industries.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Ready to start your project?

Talk to a large-scale 3D metal printing expert today! Our team is standing by and ready to answer questions or provide a quote for your project.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…