3D Printing Service

Our 3D printing services provide rapid product development and innovative digital manufacturing, from concept to execution. Leverage our industry-leading Additive Manufacturing (AM) facilities and unparalleled experience to accelerate your AM projects today.

3D Printing Service Provider

Whether it’s rapid prototyping or manufacturing 3D parts, we’ve got you covered. Xtmadeparts is a leading provider of 3D printing services, delivering the highest quality parts at competitive prices. We offer a wide range of materials and finishes for you to choose from to print your parts. Our engineers can quote within a few hours, making the ordering process faster and simpler.

When you work with us, our full team of professional engineers and designers will work with you to validate your designs, tolerances, and more. We take the time to understand your business needs, which means we ask the right questions to ensure we’re manufacturing the right parts with the right end goal in mind.

Whether you’re assembling fit and function test models, small batch production, or mass production 3D printed parts, we can help. We’ve worked with manufacturers across many industries and are familiar with the different requirements in these different areas and the regulations and requirements that come with them.

Additive Manufacturing Solutions and Technologies

As an additive manufacturing method, 3D printing uses materials such as plastics, resins, powders, metals, etc. to build parts layer by layer to achieve a component of the desired shape. The process is suitable for prototyping and low-volume production, and can produce parts with complex configurations that are difficult to manufacture using traditional manufacturing methods. 3D printing allows for rapid design iterations, allowing you to reduce time to market without sacrificing quality. It also has the benefit of reducing material waste and tooling costs.

Xtmadeparts offers a wide range of 3D printing services to ensure that you always have the right solution for your project. Whether your business needs parts, prototypes, or consumer products, 3D metal and plastic printing can add value throughout the product development and production process.

Whether you are creating a one-off prototype or a low-volume production run, we have you covered. From complex projects developed with our team to parts you print online at your own speed, we can help you in the way that works best for you.

We will work with you to expand your additive manufacturing capabilities from prototyping to streaming production. We work with you to validate solutions and support you in maximizing the efficiency of your manufacturing processes in the most challenging applications. We also enhance your supply chain capabilities through our Customer Innovation Centers to provide you with greater flexibility.

Show your designs more intuitively

You can’t make breakthroughs when your clients don’t buy into your designs, no matter how groundbreaking they are. When your clients struggle to understand your concepts and vision, there’s only so much you can do on paper. You can start over, or you can save time and skip the drawing board entirely.

High-quality 3D models put the focus on the end product rather than the process, allowing clients to experience your vision firsthand in a way that 2D renderings can’t. With well-crafted physical models, your clients can engage in the review process in a meaningful way, aligning with your vision and reducing subsequent rework. 3D printed models can enrich every aspect of a project from concept to completion, and provide a fast, affordable way to objectively review your plans every step of the way.

Our 3D printing service types

Our custom 3D printing services are designed to meet your exact needs. From rapid prototypes to full-size production parts, custom plastic or technical 3D printed parts are delivered quickly and precisely. Our advanced technology ensures high-quality 3D printed parts with tolerances as precise as ±0.2 mm.

DMLS 3D Printing Services

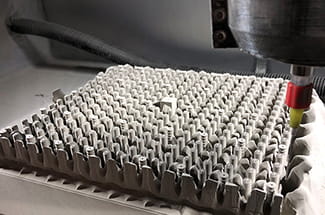

SLS 3D Printing Services

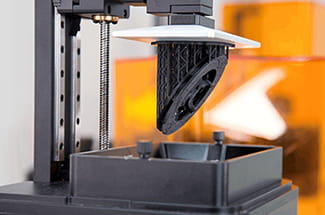

SLA 3D Printing Services

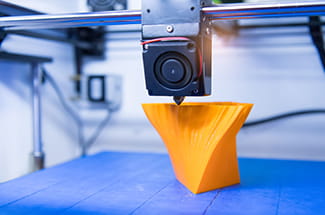

FDM 3D Printing Services

Metal Binder Jetting Services

HP MJF 3D Printing Services

PolyJet 3D Printing Services

Carbon DLS 3D Printing Services

SLM 3D Printing Services

3D Printing Plastic Materials

Our selection of plastic materials can be used for a variety of industrial custom 3D printing projects. If you have unique material requirements, please contact our engineers directly. We are committed to sourcing the materials you need.

- N6 Carbon Fiber

- N12 Carbon Fiber

- PLA

- PETG

- ESD-PETG

- CF-PETG

- PC-ABS

- PC-ABS FR

- PC PBT

- Polylite

- ABS

- ABS-R (new)

- ABS EC

- ABS ESD

- ABS Kevlar

- ASA

- UF 316L Stainless Steel

- Nylon

- Polymax PC

- Polymax FR

Metal 3D Printing Materials

Our online 3D printing service gives you access to the most professional 3D printing metal materials. Use resin materials to create plastic functional parts, functional prototypes, industrial parts and visual prototypes.

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

- Titanium

3D Print Surface Finishing

Post-processing can enhance the appearance and functionality of 3D prints, providing a smooth surface, vivid colors, or increased durability.

As-machined

Ideal for functional prototypes or internal components without aesthetic requirements.

Painting

Enhances visual appeal and durability with various color options and surface protection.

Polishing

Reduces roughness for a smoother, more visually pleasing surface on visible parts.

Electroplating

Adds a metal coating to increase strength, wear resistance, and conductivity.

Ready to start your next project?

Are you ready to start your next project? Tell the details or send CAD files for a competitive quote today.

What is 3D printing?

3D printing is a term used to describe a range of additive manufacturing technologies that produce parts layer by layer based on a 3D digital model. Some 3D printers extrude filaments to create parts, while others use lasers to sinter or solidify raw materials such as metal or plastic powders and liquid resins.

Advantages of 3D Printing

- Manufacturing with 3D printers can reduce lead times compared to injection molding because no time is spent on machining. Production can begin almost immediately.

- 3D printers can produce almost any shape from a variety of materials. Any design can achieve the desired chemical and mechanical properties.

- In applications such as rapid prototyping and small batch production, 3D printers are more cost-effective than traditional manufacturing technologies.

Application of 3D printing services

Functional Prototypes

3D printed functional prototypes enable faster real-world product development and testing before expensive investments in production tooling. These realistic prototypes replicate the final production product, including appearance, functionality, and mechanical characteristics and performance. Functional prototypes can be used to explore manufacturing processes to determine part weight, assembly processes, and overall manufacturability.

Direct Digital Production of End-Use Parts

Production-grade materials and additive manufacturing technologies provide direct production options for custom products, low-volume batches, and bridge fabrication. Save tooling costs by 3D printing directly from 3D files and take advantage of fast turnaround production part delivery. Use 3D printing to produce plastic and metal parts not possible with standard manufacturing, including topology optimized parts, consolidated assemblies, highly complex anatomical shapes, internal passages, complex surface textures, and internal lattices.

Investment Casting

Overcome the geometry and time constraints common in wax injection molding with traditional machined molds, replacing them with a fast, tool-free process that increases design freedom and improves product performance. Digital processes and additive manufacturing technologies promise significant time and cost savings.

Indirect Manufacturing and Tooling

Additive manufacturing technologies can streamline your manufacturing workflow by providing the design flexibility, quality, accuracy and material performance required for critical applications such as composite tools, molding tools, molds, master patterns and manufacturing aids (jigs and fixtures).

What parts are good for 3D printing?

Most industries require parts that are well suited for 3D printing, especially for low-volume production and prototyping. While 3D printed parts take longer to make than injection molding, eliminating the need for molds and using additive manufacturing means minimal waste and no tooling fees, which can be prohibitively expensive with other production methods.

The high strength of 3D printed parts makes them ideal for mechanical fixtures such as brackets, mounts, and housings. Even washers and large bolts can be printed if the plastic part is thick enough, but engineers who need stronger parts can turn to metal powder 3D printing.

3D printing is also well suited for printing low-volume production of parts that need to be customized. While CNC and injection molding can be used to make custom parts, their high setup costs make them only suitable for large-scale production, so 3D printing offers engineers an inexpensive way to make custom parts.

Industries We Serve

3D printing has a wide range of applications and all industries can benefit from its advantages in proof of concept, prototyping, production or machining processes. Our online services are used in many different industries listed below.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Ready to embark on tailored 3D printing services ?

Send us your 3D CAD file to get a quote for your 3D printed design. Our team of engineers will analyze and review your design, contact us today for a quote.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…