5 Axis CNC Machining Services

If you are looking for a high-precision, high-accuracy, and high-efficiency complex surface five-axis machining manufacturer, Xtmadeparts is your best partner. Contact us now to start your customized project!

Accurate Quotation

Our quotations are economical and accurate because of our professional team of mechanical engineers, who will meticulously review each drawing and will consider the nuances of actual processing, such as material deformation after heat treatment, strict tolerance requirements, grinding after heat treatment, etc. These engineers have more than 10 years of experience and have deep expertise in programming, machine operation, post-processing, material properties, etc. Ensure you get an accurate quotation within 6 hours.

Our Capabilities in 5 Axis CNC Machining

As long as you have a need for free-form surfaces, complex contours, whether the part is large, heavy, or small, Xtmadeparts can help you achieve precision machining of parts with advanced equipment and professional and skilled machinists. We specialize in 5-axis machining with tight tolerances of +/- 0.005 mm and a maximum size of 850 mm x 800 mm x 500 mm. Our machines machine all five sides of the part in a single clamping device, allowing for more precise tool path control and improving overall part quality and consistency, thereby improving accuracy and efficiency and reducing machining time.

Whether you need to produce large or small batches, one of our biggest advantages is that there is no minimum order requirement, so you can produce on demand. Our 5-axis machining also achieves high-quality, smooth surface finishes!

Finally, do you know which of your CNC machining designs require 5-axis machining? We are happy to provide you with a detailed introduction to the features and benefits of 5-axis machining and explain the specific 5-axis machining services we can provide. Parts produced through 5-axis machining are more precise and complex. With state-of-the-art equipment and our experienced team and strong manufacturing capabilities, we are able to design and manufacture complex components, even those with tight timelines.

Five-axis CNC machining quality control and testing instruments

We can provide comprehensive 5-axis CNC machining manufacturing services to customers worldwide. We always follow an effective quality control system, including inspection and control during each manufacturing process. This will ensure that all manufactured mechanical products meet the requirements before they reach the hands of consumers. There is a complete set of high-precision Carl Zeiss CMM, spectrometer, projector, micrometer, caliper, thread gauge and other instruments here.

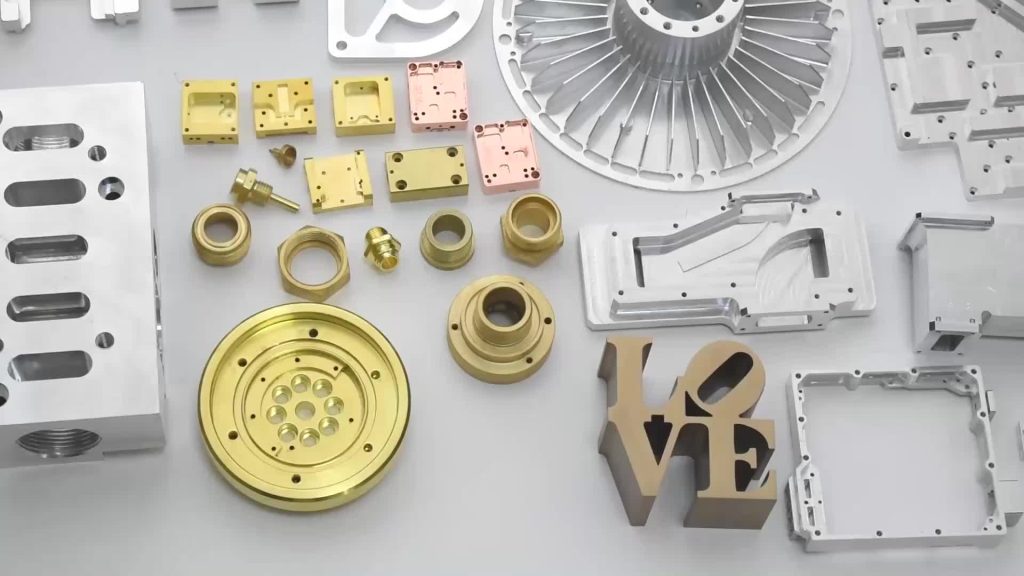

5-axis CNC Machining Materials

Our 5-axis machining services have a wide range of material compatibility. You can choose from a wide range of production-grade plastic and metal materials. No matter which material your product requires, we can provide you with professional support to ensure that you get the best material and part for your application.

Metals

- Aluminum

- Copper

- Brass

- Bronze

- Steel

- Stainless Stee!

- Magnesium

- Titanium

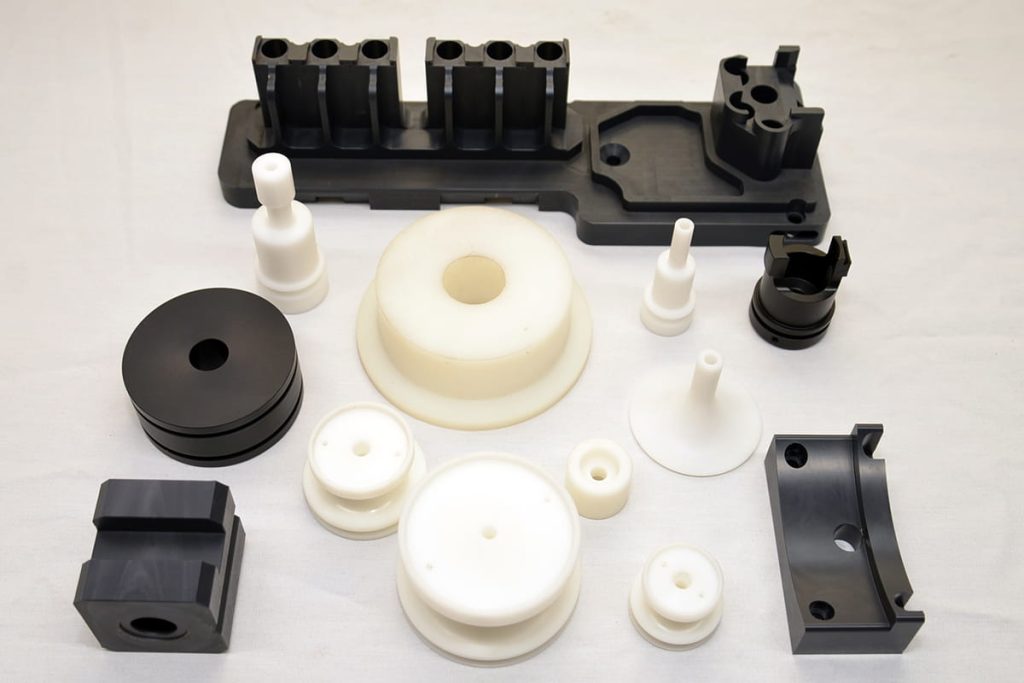

Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- HDPE

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- PTFE (Teflon)

- UPE

- Bakelite

- FR-4

Surface Finishing with 5-Axis CNC Machining

Surface finishing of parts can help improve appearance, surface roughness, hardness, corrosion resistance, and can provide additional protection, color, and finish to parts.

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Finishes for Plastic

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

Ready to start your next project?

Are you ready to start your next project? Tell the details or send CAD files for a competitive quote today.

What is 5-axis CNC machining?

5-axis CNC machining is a subtractive machining process that uses a high-speed cutting tool similar to a drill to remove a block of material. Typical 3-axis CNC machines are limited to linear X, Y, and Z axes. However, 5-axis CNC machining introduces two additional axes; rotation on the X and Y axes (called the A and B axes). The new axes allow the cutting tool to access more areas of the workpiece at various angles.

5-axis CNC machining makes it possible to get parts “one time and done”, reducing setup and repositioning costs. Efficiency and accuracy are achieved through smart programming, which allows data paths to be tried out and tool paths to be refined before production.

When to Choose 5-Axis CNC Machining

5-axis CNC machining can be used when you need to manufacture complex, precise, and delicate parts. It is particularly useful in industries such as aerospace, medical, and automotive manufacturing. Consider using 5-axis CNC machining when your parts have the following features.

- Complex Geometry: When your design requires complex shapes that are difficult to achieve with traditional machining methods.

- High Precision: When you need parts with extremely tight tolerances and minimal errors.

- Multi-axis Motion: When your design involves curves, angles, or undercuts that require complex machining.

- Time Efficiency: When you want to speed up production without sacrificing quality.

- Reduced Labor: When you aim to minimize human intervention to increase efficiency and consistency.

- Specialized Industry: When your project belongs to industries such as aerospace, healthcare, or automotive manufacturing.

Five-axis CNC machining types

Xtmadeparts is committed to customer satisfaction, providing the expertise and equipment to meet many micromachining challenges. Our track record includes providing CNC services to successfully produce parts that are difficult for other shops to produce. And, we have a wide range of 5-axis CNC equipment and technology. Our engineering team can recommend the most appropriate 5-axis CNC machining service based on your budget.

Simultaneous 5-axis machining

Fast, efficient, continuous 5-axis CNC machining for improved transitions and surface quality. Here we use 5-axis machining centers that can continuously adjust the movements on all five axes without stopping. Our 5-axis CNC machining has intelligent functions that ensure efficient continuous processes and transitions.

3+2 Axis Machining

Leverage the best of 3+2 axis machining technology for your unique application. This process holds the part in a specific orientation to allow for the usual 3-axis machining processes. Our 3+2 axis machining uses shorter, stronger cutting tools to provide better dimensional stability for your parts. Get complex CNC machined parts with tight tolerances at lower cost and cycle time.

Trunnion-type machining centers

Feature a fixed table and a spindle that moves and rotates along two axes. This design allows complex parts to be machined from multiple angles in a single setup, making it very efficient for heavy or large workpieces due to the stable support of the table.

Rotary Machining

Also known as a table-table configuration, where the part is mounted on a rotating and tilting table while the spindle remains in a fixed position. This style is particularly advantageous for complex parts that require high precision because it allows for good access to a variety of part features and can efficiently process smaller, more delicate parts.

5 Axis CNC Machining Design Guidelines

| Minimum Feature Size | Minimum feature size should be no less than 0.5 mm in width or depth to ensure structural integrity. |

| Linear Dimension | Maintain a precision within ±0.005 mm for linear dimensions to ensure accuracy across the machined part. |

| Hole Diameters (not reamed) | Holes can be machined with diameters starting from 1 mm up to 40 mm without reaming for precision sizing. |

| Shaft Diameters | Shaft diameters should range from 2 mm to 300 mm, considering the tool accessibility and torque requirements. |

| Threads and Tapped Holes | Threads from M2 to M24 can be machined. Ensure to provide adequate relief at the bottom of tapped holes. |

| Text | Minimum text height of 1.5 mm with a depth of 0.5 mm for clarity after machining. |

Manufacturing Capabilities for a Variety of Industries

Using state-of-the-art 5-axis CNC machining solutions, we develop customized, cutting-edge technology platforms for a variety of manufacturing industries, including aerospace, healthcare, electronics, and drone production. Our advanced capabilities provide a unique competitive advantage in part size, material selection, finishing techniques, and customer service.

Aerospace

Automotive

Medical

Consumer Products

Oil and Cas

New Energy

Semiconductor

Robotics

Industrial Equipment

Get an online quote and manufacturing analysis today

Are you ready to start your next project? Tell the details or send CAD files for a competitive quote today.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…