Services

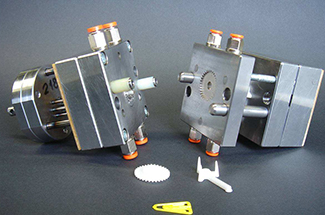

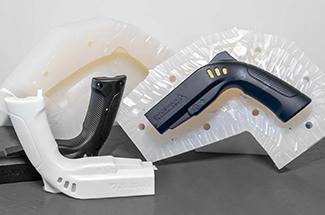

We have extensive experience in rapid prototyping and rapid manufacturing, including: CNC machining services, injection molding services, metal or plastic 3D printing services and sheet metal production services, etc., which enables us to make full use of metal and plastic prototypes to make many different types of projects. Moreover, we will transform your ideas into marketable products in a very short time, which helps to quickly launch your ideas.

Rapid Prototyping and Production Manufacturing Services

We are committed to providing our customers with the highest quality rapid prototyping and production services. We pride ourselves on providing a higher level of customization to meet your exact needs. Our sales engineering team supports you at every stage from initial product development to mass production.

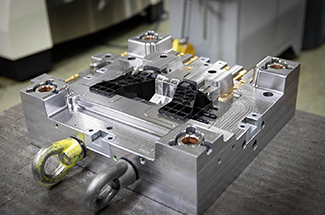

CNC Machining

Injection Molding

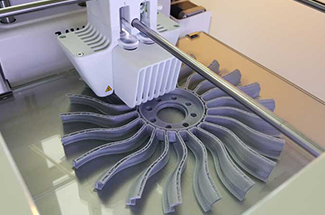

3D printing

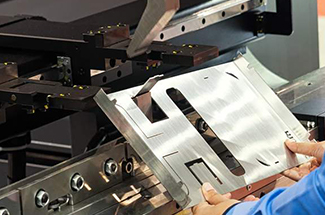

Sheet Metal Production

Rapid Tooling

Vacuum Casting

About our company

With our diverse equipment, our company can meet all of your custom parts needs. We can provide first-class custom processing of metal or plastic parts, full project management, assembly and logistics services to help you streamline your manufacturing process. Our comprehensive on-demand customization services can help you save money, reduce overhead, shorten time to market and improve overall product quality. Our mission has always been to help our customers produce as many high-quality products as possible to meet their needs, regardless of shape or size.

HAPPY CUSTOMERS

SQ. METER AREA

PARTS MADE PER MONTH

Engineering Support

Xtmadeparts’s technical talent provides detailed design recommendations to improve the manufacturability of your parts. Our online chat system provides immediate, on-demand resolution of issues. In addition, Xtmade offers dedicated services to efficiently execute large customer projects.

Start today. Get parts made fast.

Are you ready to start your next project? Send us details or CAD files for a competitive quote today.

News & Article

Get our news, resources, and events.

Metal 3D printing vs. CNC Machining: Which is better for prototyping and end-use parts?

In the world of manufacturing, two cutting-edge technologies…

3D Printing Techniques: Different Types of 3DPrinting

In recent years, both academically and industrially, additive…